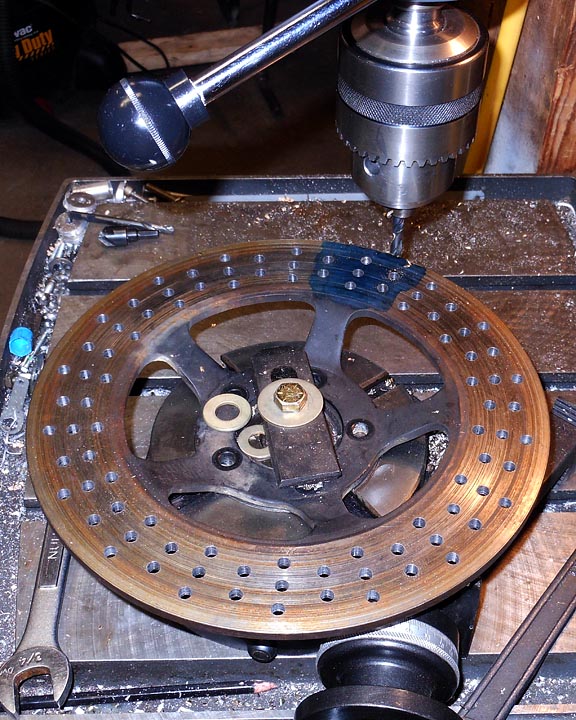

Just a quick progress report on the CX 500 Cafe Racer Build project, I’ve cross drilled the rotor using a rotary table. This was surprisingly quick once I dialed in the rotor to the rotary table eliminating any run out. It went so well that I suspect I will be cross drilling lots of rotors in the future.

I stripped, sanded, and painted the front rim with some quality satin black wheel paint and it looks awesome. I used a large plastic tub that fit the wheel and wet sanded the entire thing by hand. Sandblasting would have been considerably easier but my blast cabinet is not large enough. Sanding all of the backside and the nooks took forever. Next time I would pay to have it blasted at a shop. It came out looking awesome though and I can’t wait to see the now completed front end reassembled on the bike.

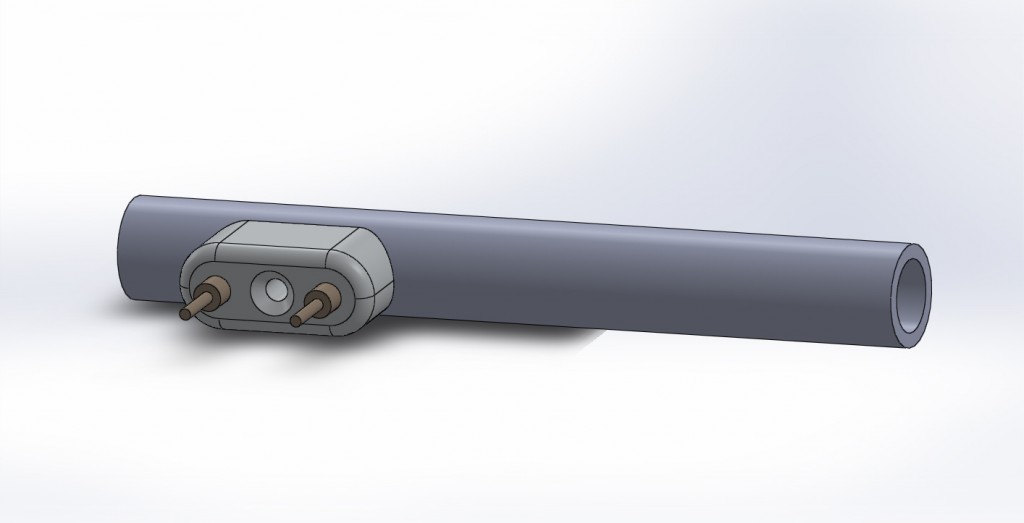

You have to use your imagination a little bit for the above image, but this is the 3d model of the handle bar switches I will use on the bike in place of the stock ones. I will have the CNC machine bang out two of these. They can each house 2 switches or buttons. I ordered the right size cutter some time ago to make these and plan to get them machined in the coming week. The wires will run through the handlebars and it will be a nice clean installation.

Above is the battery box on the bike. I built this to relocate and clean up the install of the battery and starter solenoid on the bike. I’d like to get a mini ATO fuse block that mounts through the side of this as well. I will sandblast and paint the box satin black, even though it’s made from 316 SS. Here’s a pattern if you want cut and fold a battery box of your own for the CX500: battery box Sheet metal pattern for Honda cx500 cafe racer build

You can see the battery and solenoid fitment in the belly box. Sadly it warped a bit when I welded it up. I did not take my time and regret it. I’ve hammered it back a bit and used the press to get it to fit comfortably in place. You can not tell on the bike but seeing it from the top like this it is apparent that it is a bit skewed. I will make a bolt in hold down strap for the battery and this bit of custom fabrication will be 100% done. I will need to address the wiring as well in the reassembly stage which I am fast approaching.

That’s all for now, more soon as I want to get this project finished and out the door ASAP.