I’m big on recycling and feel the highest form of recycling is to re-purpose and reuse things that would otherwise be discarded. This project is built largely from re-purposed recycled components. It’s fabrication used 3d printing, cnc machining, electronics, and woodworking. The inspiration came about when I was visiting my buddy and he asked me to help him move a giant older DLP television out of his basement to the curb. Realizing it was going to the dump, I asked if I could take a few useful parts from it. Originally planning to only grab the connector plate off the back that I needed for another project, we ended up taking the TV apart and I recovered the power supply unit, speakers, some circuit boards and the connectors I was originally after. Research online showed that the speakers were really quite nice units, fully shielded with decent Theile/Small specifications. There was an onboard self contained amplifier chip in the TDA family that was easily desoldered and built into a small stand alone audio amp. I had been wanting a small nice powered speaker unit for some time and I now had all the parts I needed to build myself one.

I went with a slightly retro design for this unit. I didn’t really reference anything outside of some basics, like the golden ratio and standard speaker enclosure practices. I’m very happy with how it looks and sounds. I think it’s very attractive, fitting well with the rest of my things.

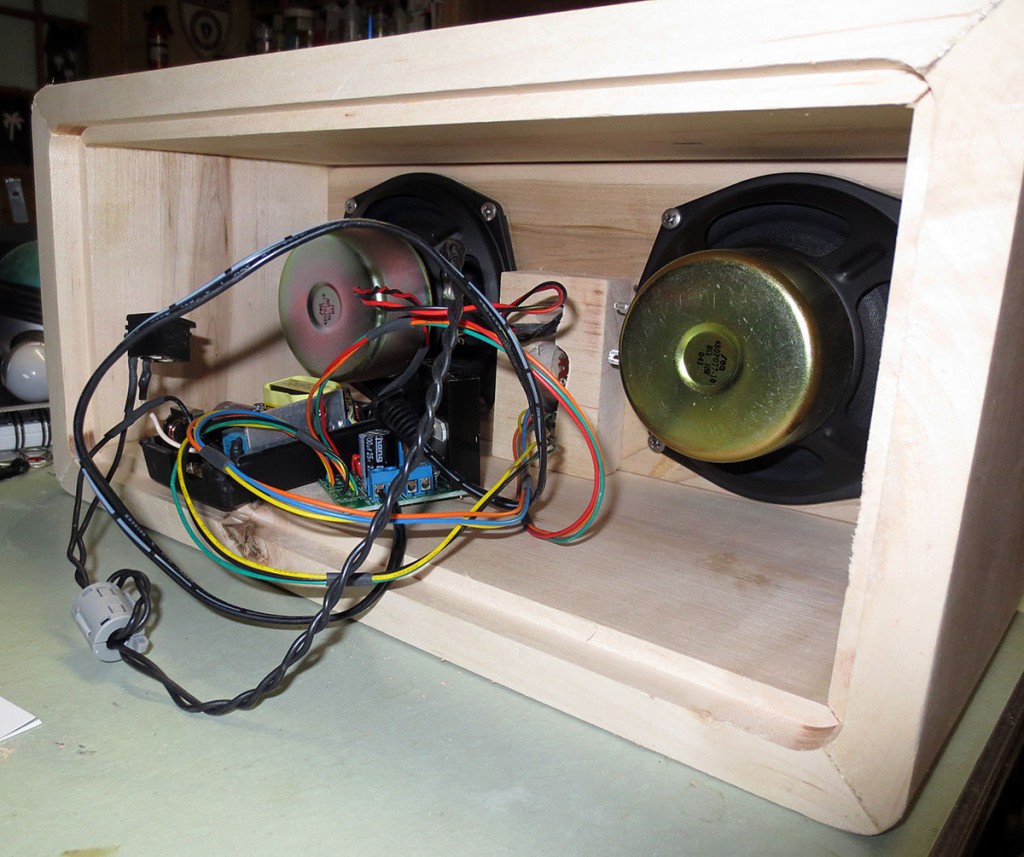

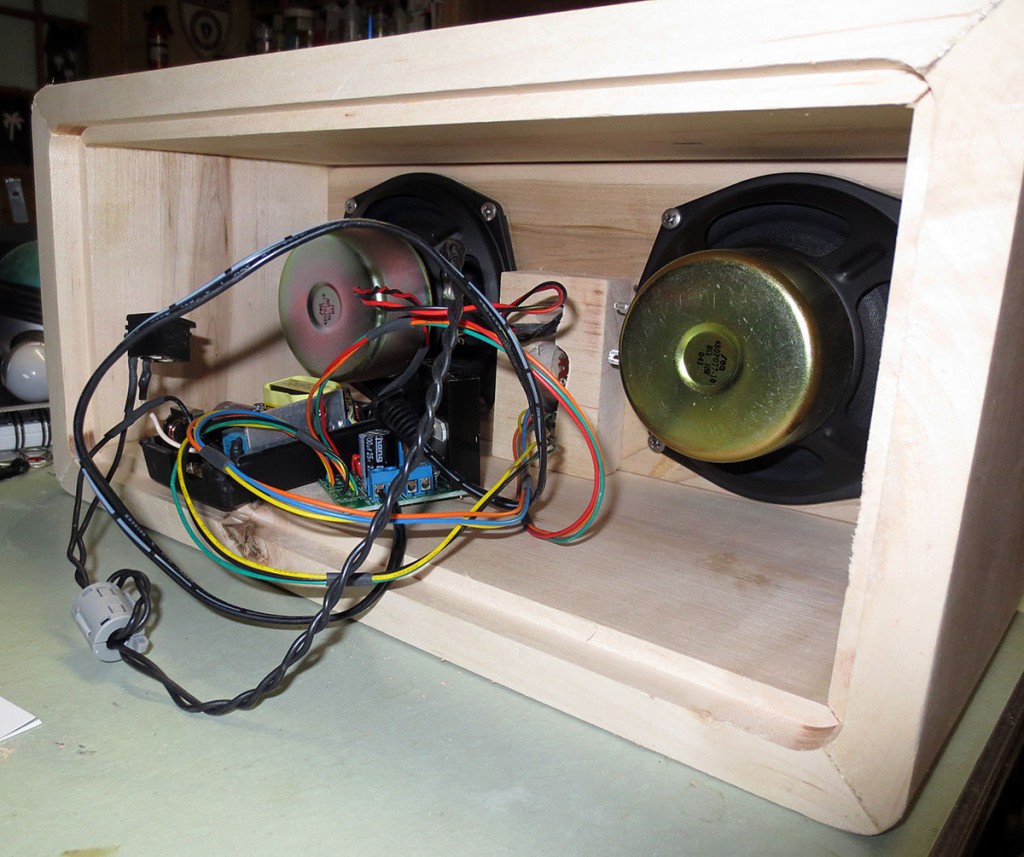

Before buttoning it all up there was several rounds of testing out the electronics, switches, power supply, etc to ensure everything worked correctly. In the end I removed the screw terminals on the PCB and soldered the wires directly worrying that they might come loose with vibration from the music.

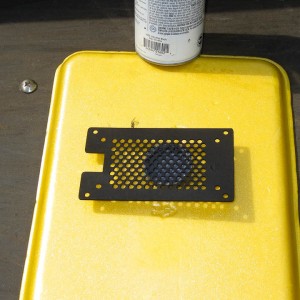

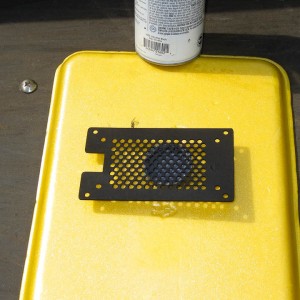

The amplifier housing on the left is 3d printed in ABS, as is the power supply housing on the right in the above photo. I went with a machined metal vent/cover plate milled on my converted CNC machine. I’m a big fan of Krylon’s ultra Flat Black paint and used this on the back cover for a nice matte black finish.

The power supply is a standard unit I kept from some piece of electronics that was out dated. A few minor modifications, remote plug, switched line inputs and an active LED on the front panel all were done the power supply. Then I designed and 3D printed a case to mount it safely into the speaker unit.

The lighter wood for the outer bodycame from a storm downed maple that I milled into lumber three or so summers ago and dried. The front and back boards came from a log off a riverland maple my lifelong friend’s father let me take when he cleared some off his property a couple years ago. Even the front plate is machined from aluminum recycled from an old PC case.

The finished speaker unit sounds amazing. I missed a few pictures in the build process. The inside is fully sealed with a divider keeping the two chambers separate. I also used some polyester batting as internal dampening to increase the effective internal “volume” of the speaker enclosures. This unit survived a 48 hrs continuous stress test without any issues. I love how it looks as well as how good it sounds!