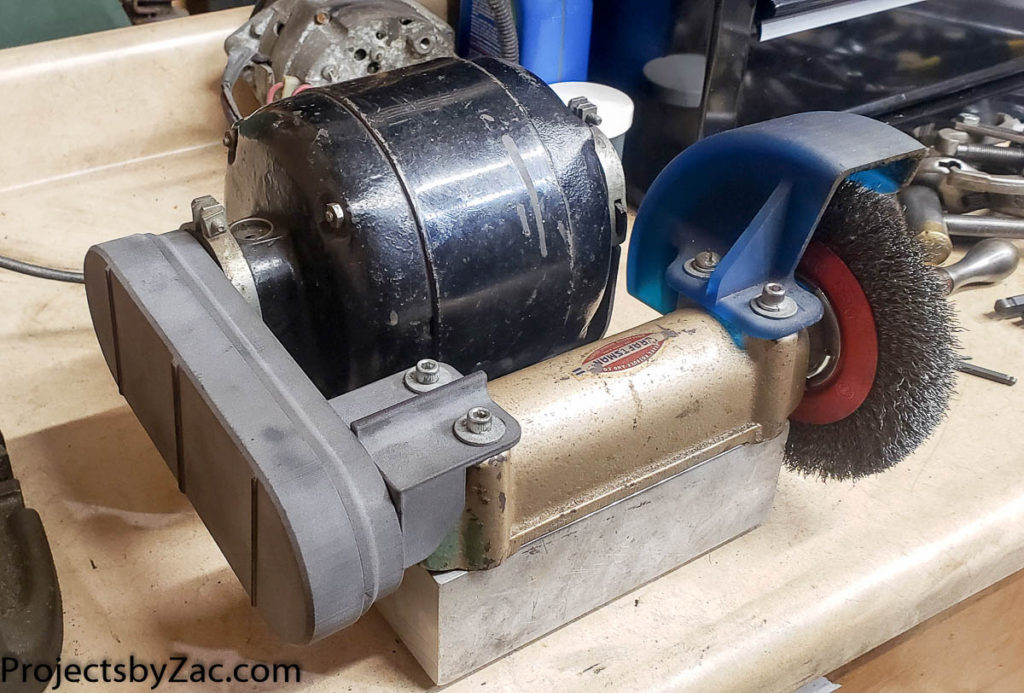

After dissassembly of the Tiny Dozer’s 3 speed transmission I cleaned, polished, removed rust, and carefully filed (or ground) off any burrs on each component of the drivetrain. I have this great tool I build for the bridgeport restoration last winter, it’s a heavy belt driven bench mount wire wheel. I used this a lot again on this project. The fat welded wire wheel makes quick work of rust, paint, and any gunk left after solvent soaking parts.

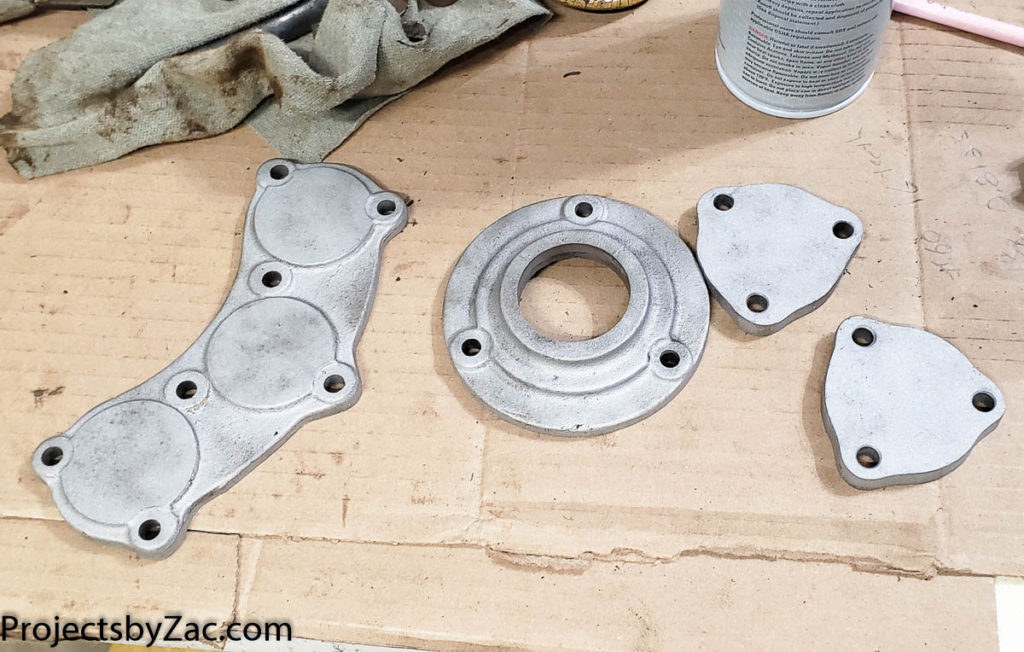

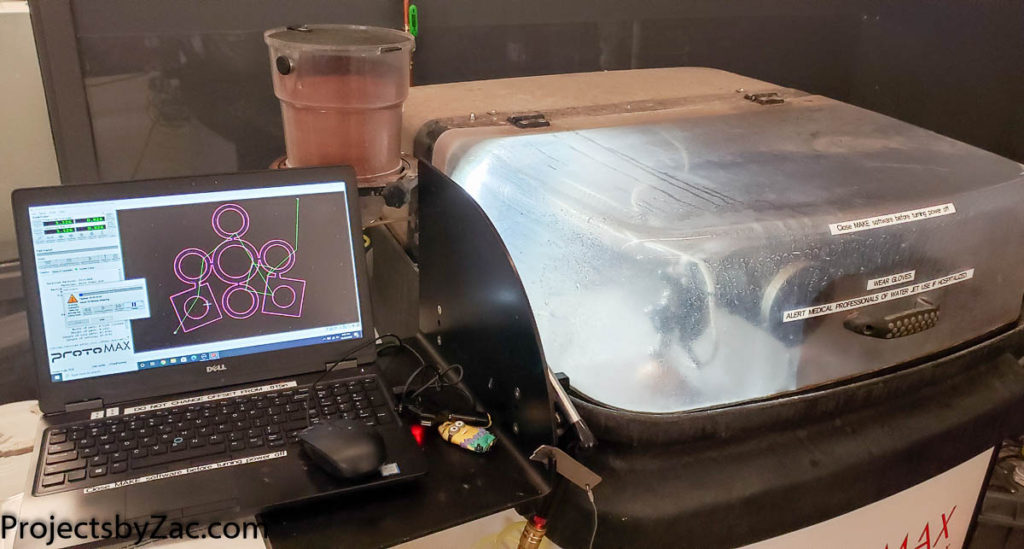

I chose to laser cut new gaskets. Thankfully the ones I had were ok enough to scan. The process for making new ones is Scan, Clean up the file, turn to vector paths, make into PDF, import into Laser cutter software, cut from gasket material. I’m using Cometic Gasket Fiber Gasket Material (Part # C15385) that I picked up at my local Autozone.

Here is the pdf of the Gasket cutting file for you to use if you would like to laser cut your own set of gaskets. You can also print this out and use as a template to cut by hand with a bit of care to get new gaskets for your transmission rebuild. <INSERT FILE HERE>

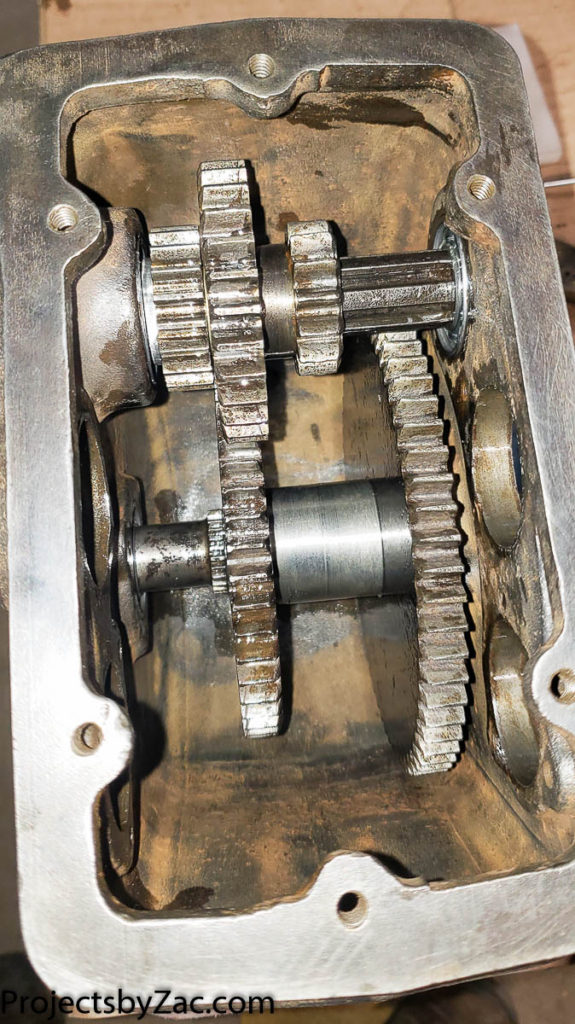

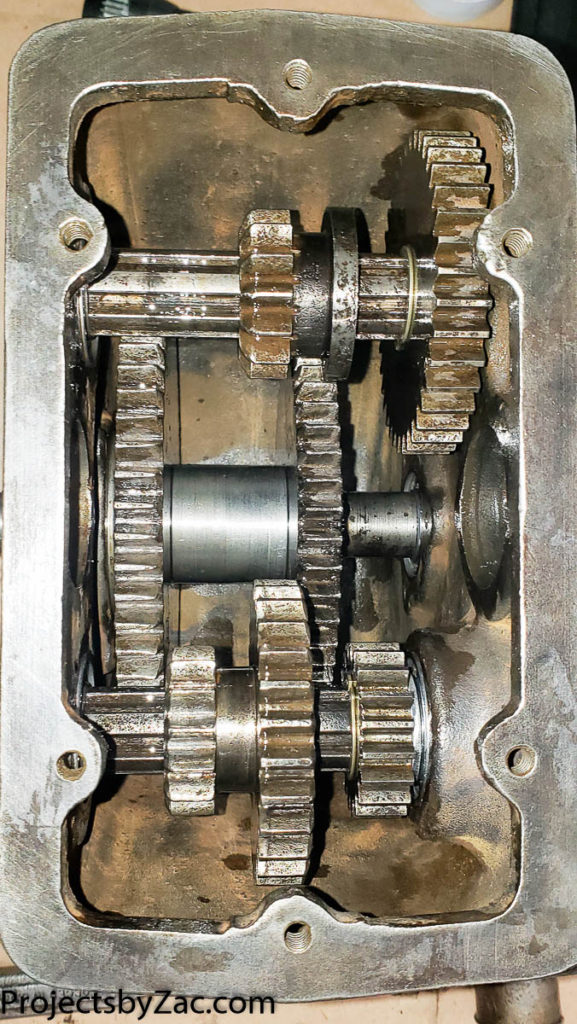

The reassembly starts with laying everything out as it will go together and making sure you have all of the parts. It was at this point that I realized many of the stand off spacer washers were badly worn. They were stampings from 1/8″ steel. I decided to quickly cad up and water jet some new spacer washers before assembling everything.

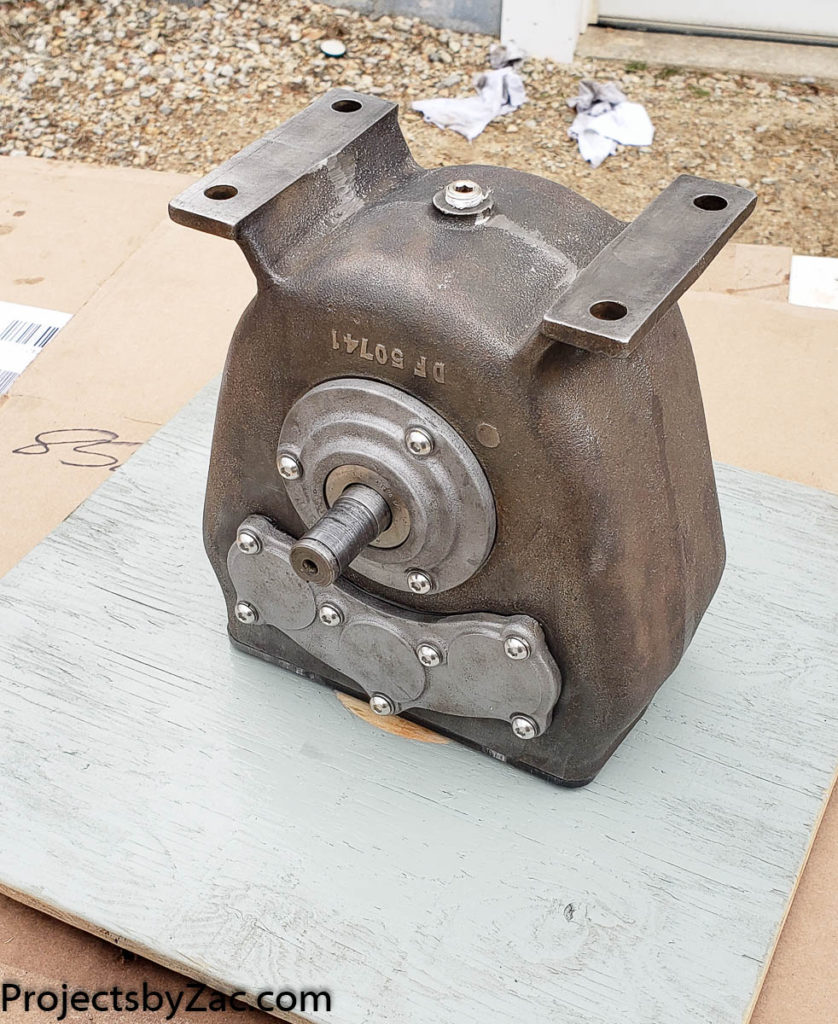

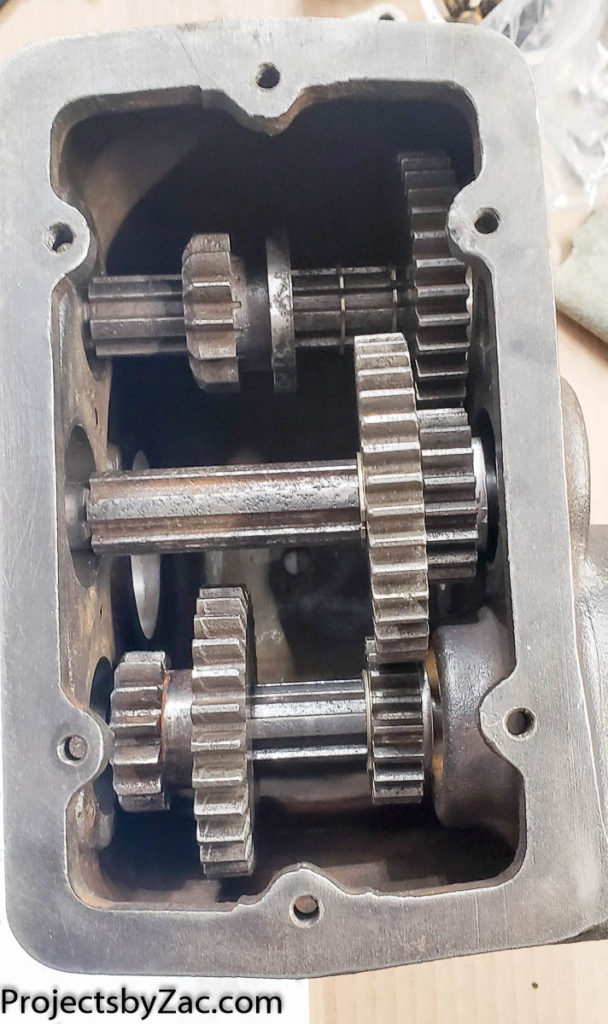

With new spacer washers made I was ready to figure out how to get it togethere. The spacer washers ensure the gears are not rubbing on the bearings/sidewalls of the housing body. I would like to say I nailed assembly after this dry fitup without bearings, but as you’ll see below, I did not get it on the first go.

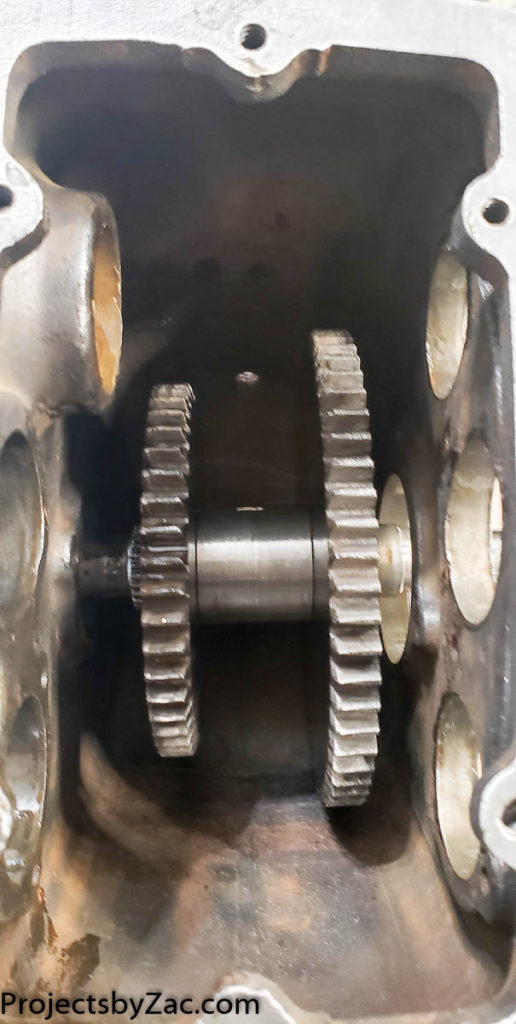

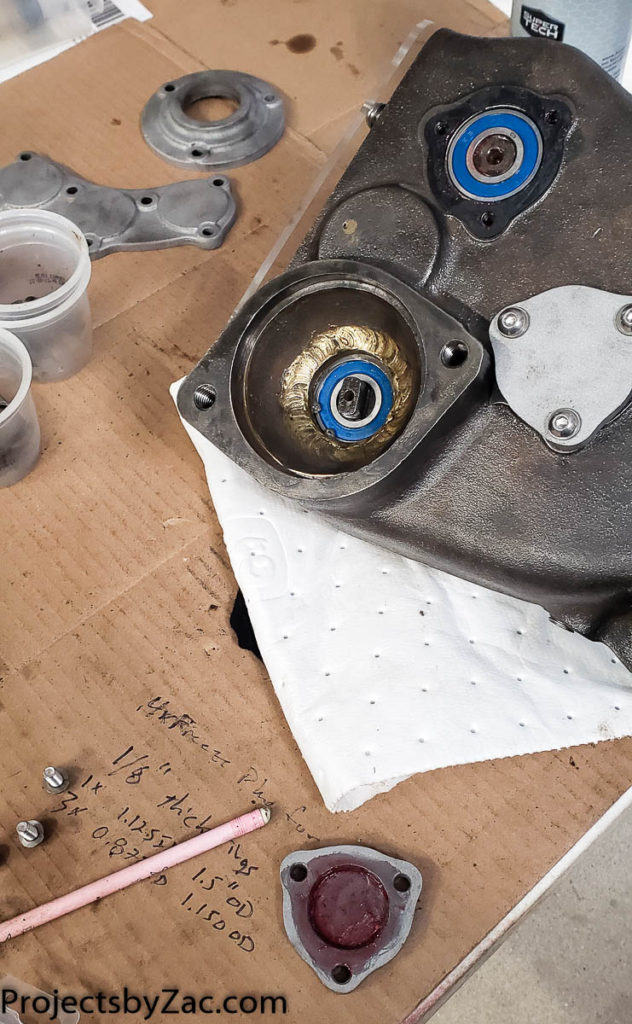

After loose fitting everything, I took it all apart, and got ready for the final assembly. I started with the lower output shaft with the two large gears. I did replace the snap rings throughout. I happened to have a bag of the appropriate sized snap rings in stock. Most of them are for 3/4″ Shafts. The one on the main shaft is a 1.25″ shaft (a 32mm snap ring will work as well if you have one). I put replaced the 1/4″ npt drain plug with a SS hex plug. I really hate cast iron square plugs.

I’m using a cheap GL5 gear oil with lower viscosity. I plan to change this out multiple times post rebuild after very short operating period of an hour or two. This will help wash out any bits that I might have missed cleaning pre assembly. Be sure to lube everything up as you assemble it. I made care to get lots of the gear lube in the splined areas on the gears and the shafts. GL5 type oil is ok, as there is no copper, or copper alloys in this transmission anywhere. The EP additives in GL5 can corrode and destroy copper alloys quickly. If I end up making a cast barillyum copper shift arm (I can’t cast steel/iron but need the strength) I’ll switch to a GL 4 or standard motor oil lubricant.

One note on assembly, don’t think you will casually knock this together with a hammer and block of wood. The press fit clearances are pretty tight. I ended up using my big 20 ton hydraulic press to get most of this together (no photos of this as I didn’t have a tripod or photo taking helper available with Covid pandemic in full swing)

A quick note on the bearings. When I took the 3 speed transmission for the bulldozer apart, all of the bearings were open race with no shields or seals. I decided there was no reason the outer side should be open race. Also I could not find affordable good bearings that were not shielded. It’s pretty easy to pull a shield off of a bearing, and I did this on the internal side for each of the seven 6203 bearings as I assmebled them with a hook pick tool.

The first shaft assembly went together well. I thought I was home free. Things went ok, until I got to the last shaft, and then it didn’t work. I’m sure if there was a manual they would explain the proper assembly, but I have no information on this thing. In the end I had to press a bearing most of the way out to get the shafts and bearings all assembled. The photos below have me pointing at this bearing/shaft I had to shift with the hook pic tool.

Other than the above, the assembly was straightforward. I’ll drop pics in the gallery below for your education and enjoyment. Drop a comment if you have any questions.

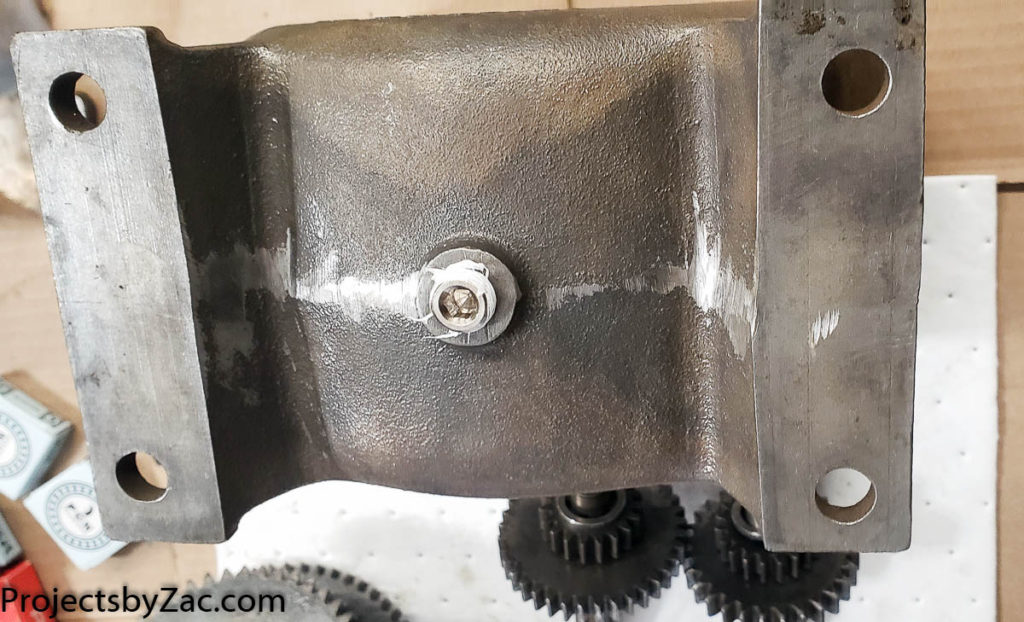

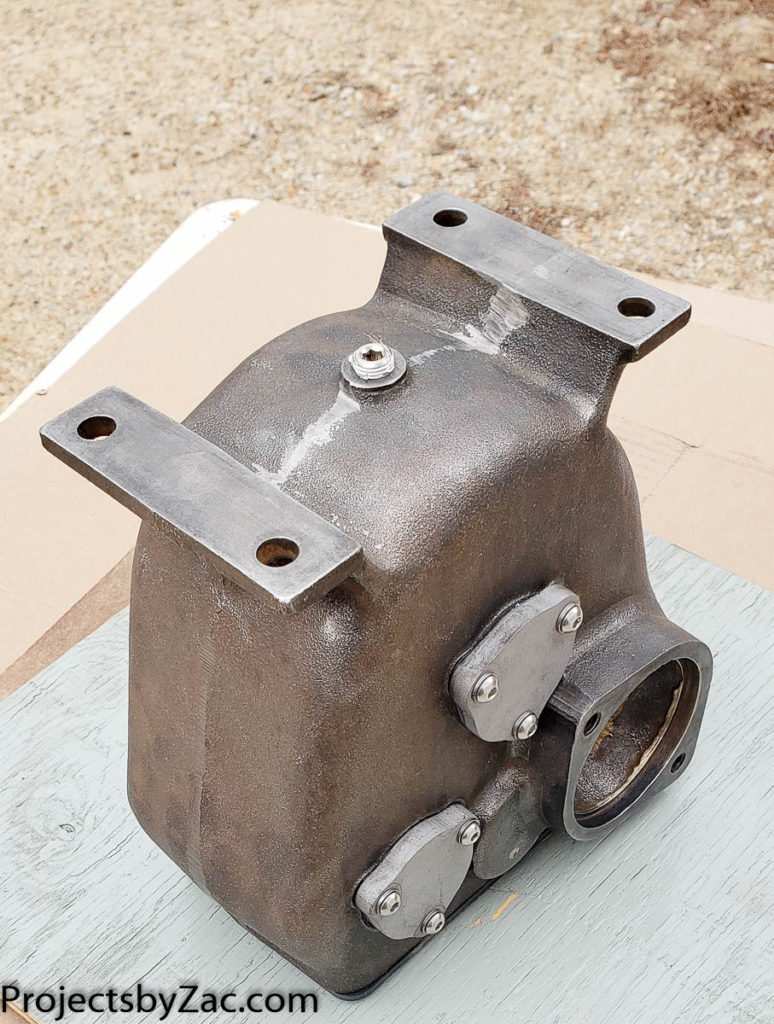

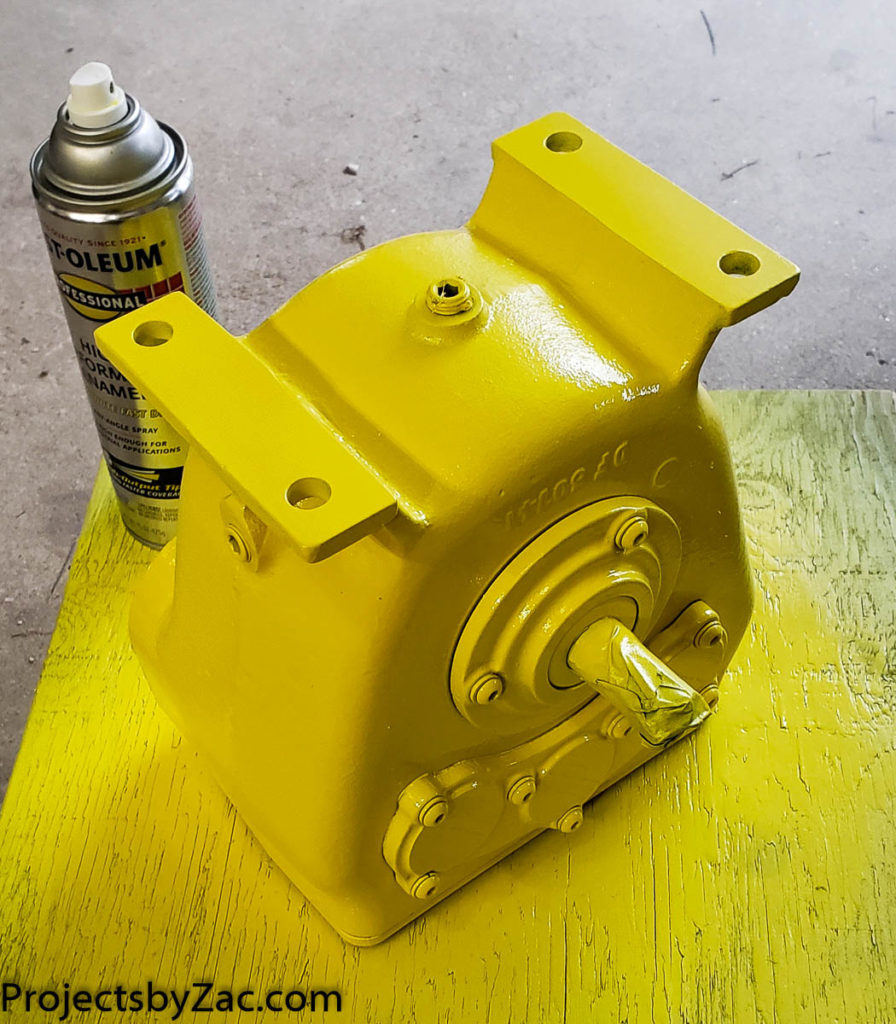

Painting in the winter is tricky, I often spray outside and then quickly bring the part in for heated curing. A big torpedo type heater 3 feet away goes a long way to cure and dry the paint quickly. I’m not sold on this safety yellow collor. I’ve left the botom end masked for now, as I suspect I’ll paint it with a different color yellow.

As always if someone stumbles across this page with any information about these Trackmaster d-Fab Engineering by Fruehauf Trackmaster Dozers Crawlers, I’d love to know more about them. I’d be happy to host manuals and or parts catalogs here on my blog if you have them and are willing to share them with me. Please leave me a comment or email me at my website name on Gmail (no dot com there). I don’t check often, but I eventually will get back to you to host the information. Thanks!