It has been some time since my last post. Summer is the time for swimming, sunshine, adventures, friends, fishing, and so on. All of that has been keeping me pretty busy these days. Here’s a post on a recent project to keep you entertained. I needed a spindle locking mechanism for my large drill press to help me convert it into a wood branding press. The nice thing about having the CNC milling machine I built for myself is that when I need a part or machine I can readily make it. It’s hard to imagine how I survived in the days before having CNC machining in the shop.

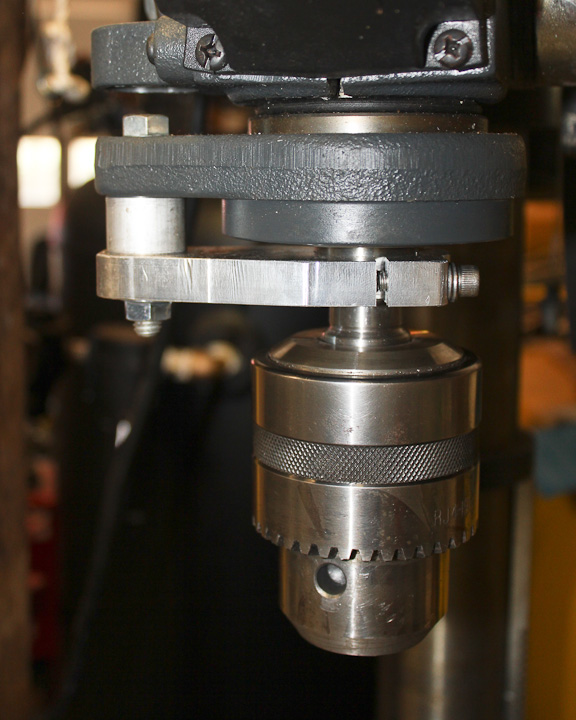

There was no built in spindle locking mechanism for my industrial drill press, and no add-on accessory available for purchase to lock the spindle. I decided to take action and design my own add on mechanism. I feel the best way to lock the spindle was to clamp the lower spindle were the Morse Taper socket is located on the bottom of the spindle (shown in the photo above). I originally toyed with a removable pin mechanism in the spindle itself, or clamping the belts up top somehow. Both of those ideas seemed more difficult then the solution I will share in this post.

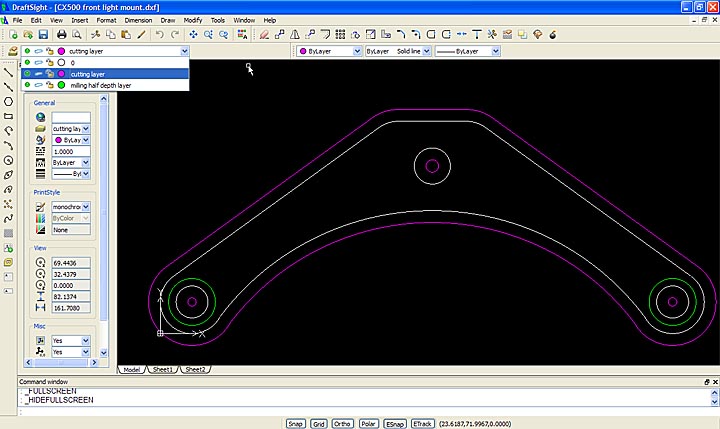

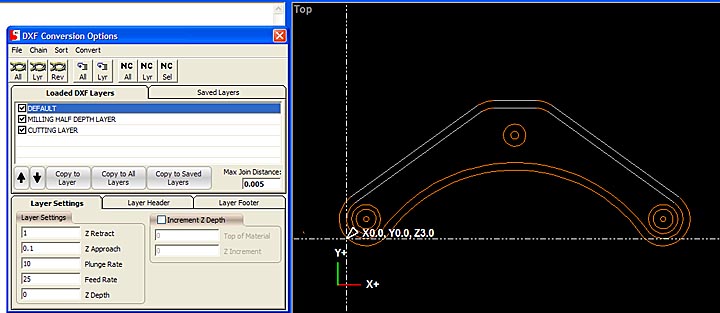

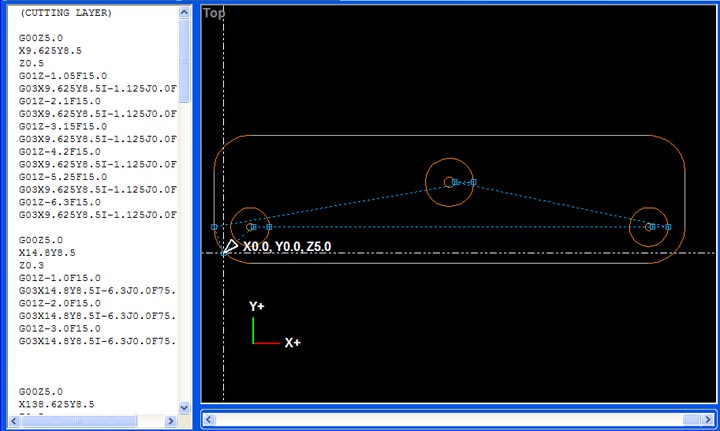

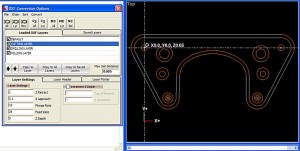

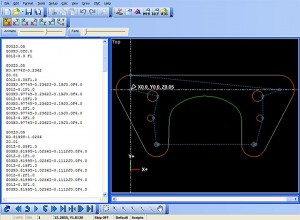

I started with a piece of half inch aluminum stock. This was an old adapter plate from some work years ago. As such it had a few holes in it. I carefully selected the origin of my part such that the machining would remove the material where the existing holes were located. This careful setup up allows me to reuse scrap stock or old material from previous projects. The next set of photos are just time lapse photos of the machining for your oogling pleasure, as such I will not comment much on them.

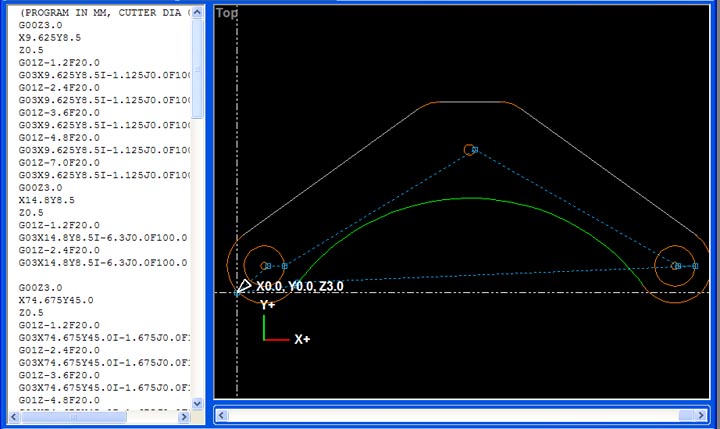

As you can see the finished part was milled out of the aluminum stock. The only real downside to machining parts this way is at the end you are left with a small very sharp triangular nub on wherever the cutter started out. I simply file this material off by hand. For more exacting machining work, I would have made a jig by drilling and taping mounting bosses inside the part somewhere, this way the profile would be machined completely, resulting in a higher quality machined part.

The part took 30 minutes to machine. I might have been able to push up the machining speeds but I’m reluctant to push the speed as I do not want to break my end mill. This was my first part cut with the new HSMworks software I installed thanks to learning about the free version from Jim Wilkinson on Facebook a while back when he saw a previous project post. Thanks Jim!

The next step after the CNC milling of the drill press spindle lock’s body was to drill and tap a single clamping screw. I used a 1/4″ – 20 tpi tap. I tend to use quarter twenty bolts for just about everything not load critical in my designs as I stock a large variety of bolts in that size in my shop. Simplifying your designs by using only a few standard threads for all of your projects is a good idea for hobby projects where weight is not a concern.

Above you see the more or less finished spindle lock assembly in place. I had to take the left side depth guage/stop assembly off, but as this is only a single nut it takes less then five minutes to put on the spindle clamp. I cut the slot out in the wood shop on a miter saw with a thin kerf carbide tipped blade. I could have milled it but it is very fast to use a saw blade for slitting operations. The only thing missing from this picture is a spacer to clamp down on and lock everything tightly in place.

Above you see the finished spindle lock assembly. I quickly turned down a bit of 1″ aluminum round and made a spacer of the right size. She’s all clamped down and I am now ready to do some wood burning with our new electric branding iron.

I hope to be more active in posting both here on projectsbyzac.com and photosbyzac.com in the fall. August is chock full of good stuff and will likely keep me too busy for regular weekly posts. But stay tuned in the fall, the 3D printer project will be finished before christmas (personal goal). There will be lots of posts on that as well as continued upgrades on the CNC milling machine and the completion of the Cafe Racer Honda CX500 motorcycle.