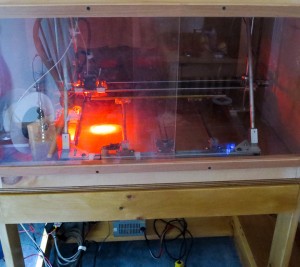

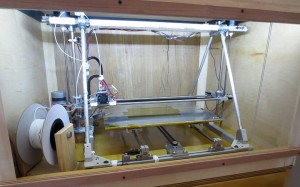

With my 3D printer dialed in and tuned up, I was still having issues with the temperature on the heated bed and parts warping. I determined that this was due to external air currents in the room. I had been considering building a permanent table for the 3D printer and added an enclosure to my design to eliminate the effects of drafts on printed parts. The enclosure is nothing fancy, very low tech in fact. It is a corner framed box made from 1/4″ luan plywood with sliding plexiglass front doors. It has handles and easily lifts off for maintenance and upgrades.

The table is made from 5/4 pine lumber I had cut a few years back when the electric company cleared power lines along the property. It has a full width drawer that slides out fully. I needed a place to hold the tools and parts used to maintain the 3D printer in tip top shape. The small shelf in the back keeps the power supply and other wiring off the floor for better airflow and cooling of these units.

For now, my 3D printer is driven by a computer and it has a nice new workstation courtesy of my good friends Mark and Michelle who donated the computer desk to the cause. I also use this computer for development and programming of other projects like; Tetro the quadroped robot and Filastruder the filament extruder that will feed the 3d printer filament made from recycled plastic, and other cool things I’m not ready to leak to the public at this time. 🙂 Have no fear there will be blog posts on tetro and filastruder as I find the time.

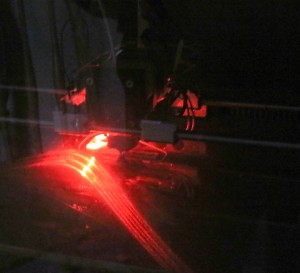

Adding the enclosure required some necessary additions to the printer. First was lights on the print head. I used to not understand why people would put lights on their print head, but now I get it. When it’s running it’s important to monitor filament laydown and in the enclosure it’s pretty hard to do so without the lights. I added three high brightness LEDs aimed at the print area to the left side of the x axis sled.

I used 12V SMT LED light strip which is readily available from online suppliers to light the entire enclosure. The above photo shows the strip attached with a pressure sensative adhesive strip to the inside front of the printer enclosure. The 30″ of light strip provides more then enough light for the enclosure.

Above photos show the effectiveness of the LED light tape. Left photo lights off, right photo lights on. A worthy addition to the printer.

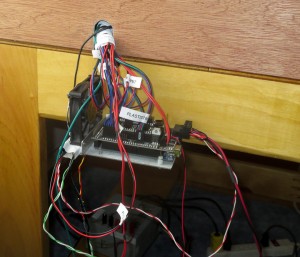

What’s left to do to the printer before it is done? My next steps will involve some changes to the control interface and enclosing the electronics that drive the printer (seen in the above photo). These changes will turn my 3D printer will be a true stand alone machine with an LCD display, control interface via buttons and dials, and an SD card reader. This will eliminate the need to have the PC running or even connected to the printer for operation.