One of the known problems with the MP Select Mini 3D Printer is that the power supplies burn out. The Monoprice Select Mini IIIP 3D printer uses a 12V 10A external power supply that plugs into the back of the printer. If you leave these on carpet, cover them with anything, or just get unlucky you can burn out the power supply pretty easily. If that happens, I suggest buying a bigger 12V power supply rather than a direct replacement.

The printer in preheat mode with both the bed and the nozzle heating up is pushing this switching power supply pretty hard. It gets hot to the touch from the load in this use condition. Any lack of airflow/circulation around it will cause the power supply to die. Someone at work put a stack of papers on the first one I purchased and this caused the power supply burn up and fail. My personal power supply on the mini at home lives on carpet and needs a riser to let air circulate to keep it cool so it will live a long happy life.

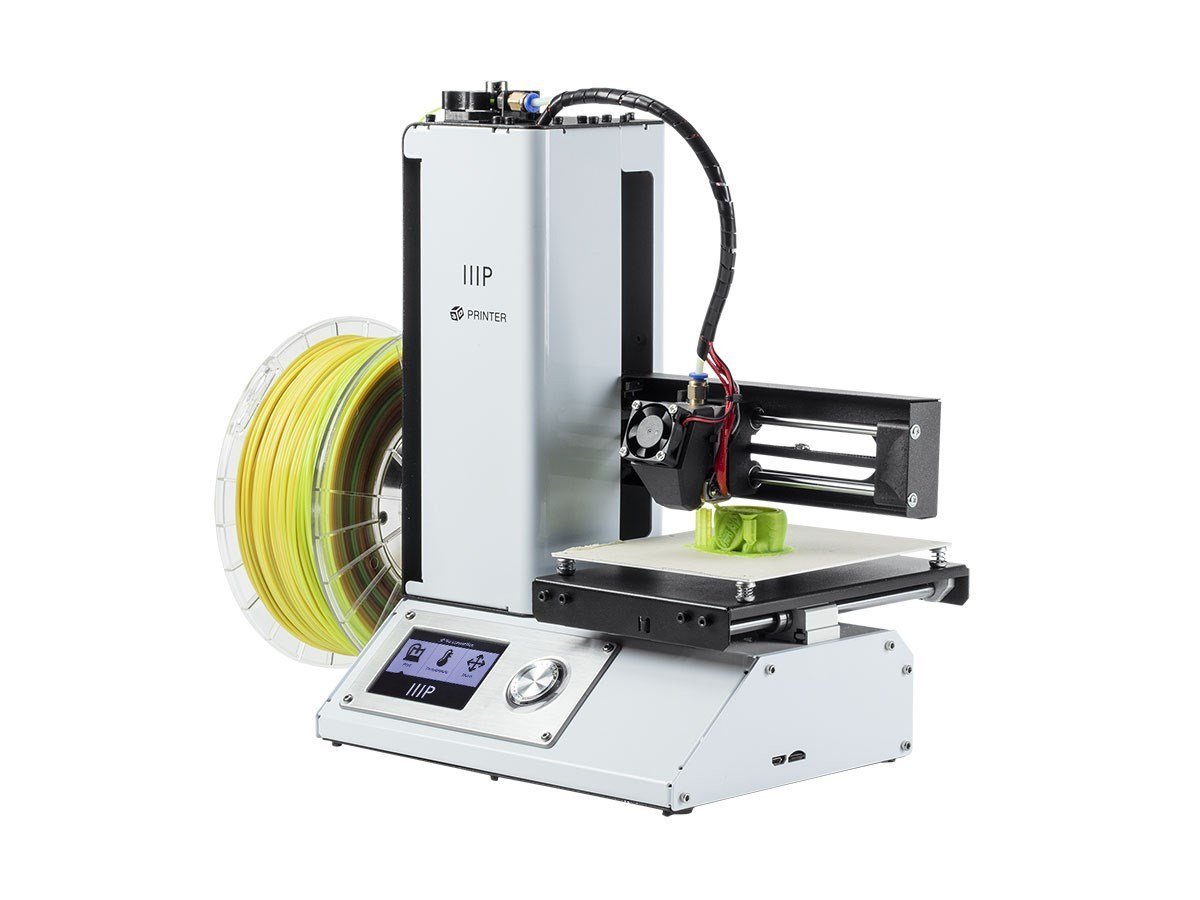

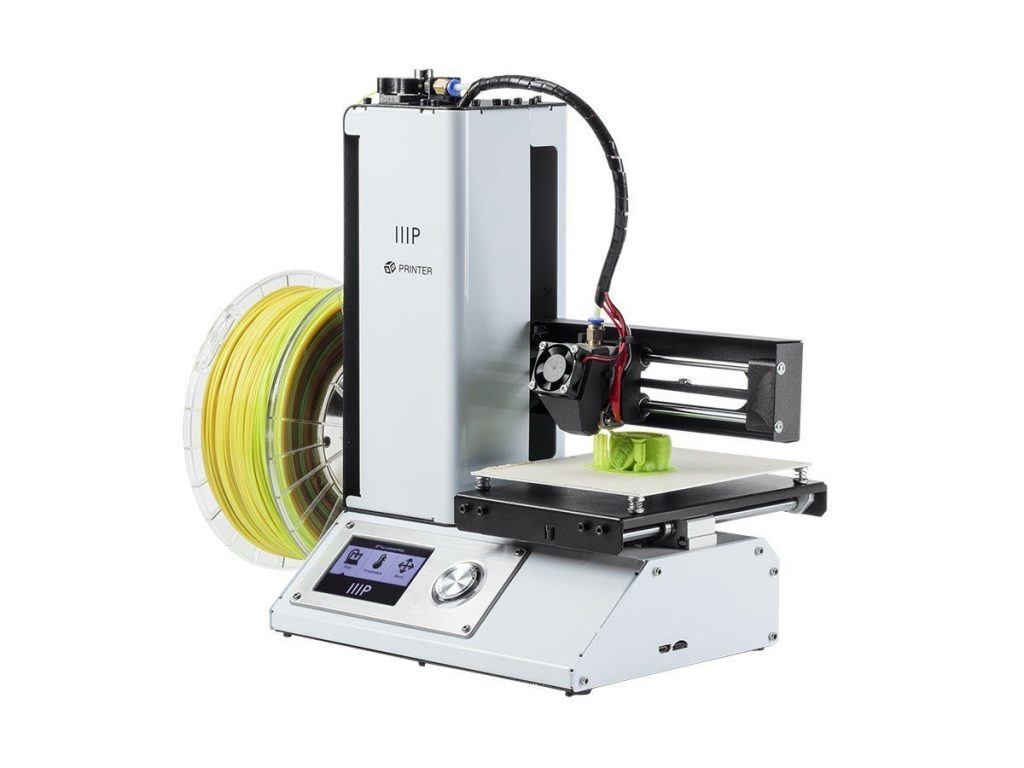

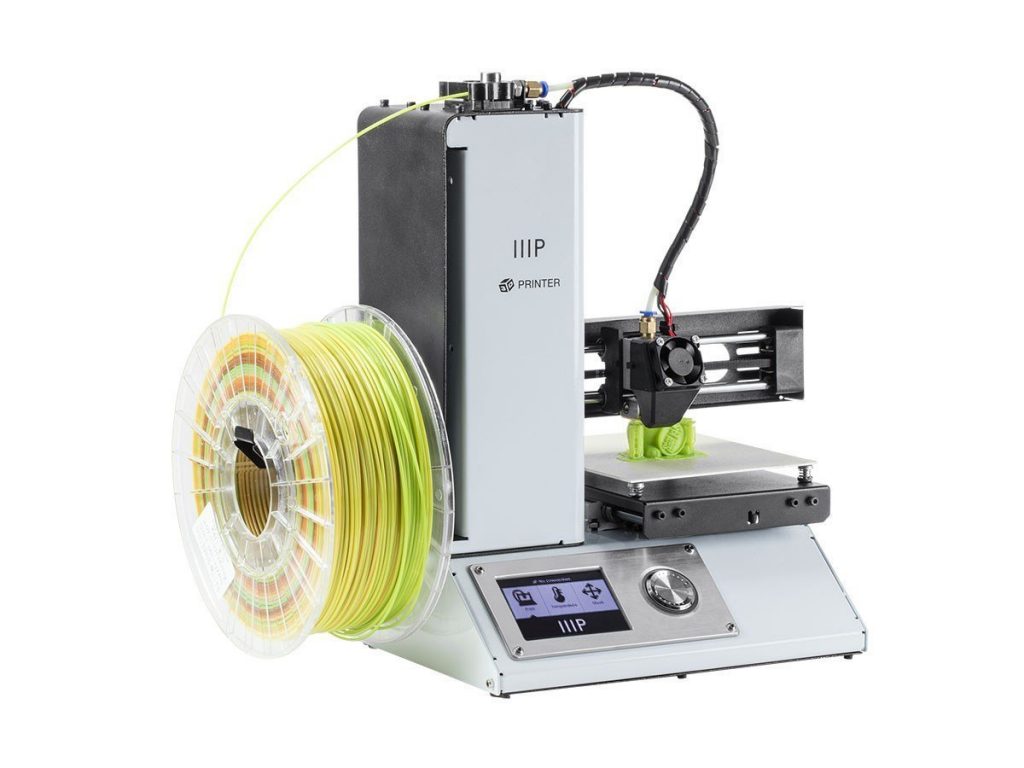

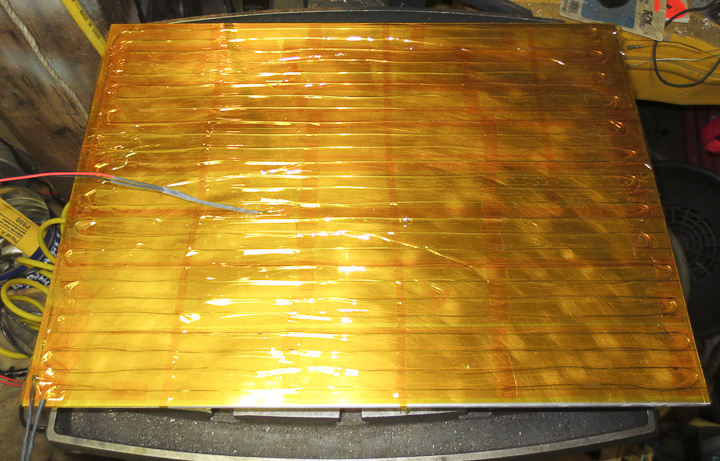

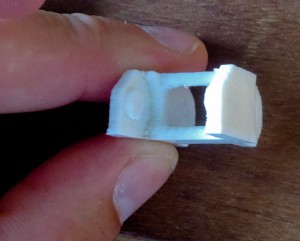

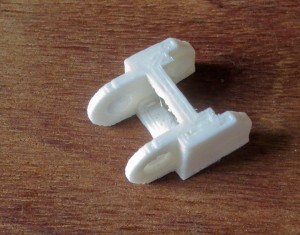

I had my DJ laptop power supply burn out years ago after it ran too hot for too long. For the very expensive replacement I made a 3D printed cooling riser stand for the power supply that worked awesome to keep it cooler. I made one to fit the Monoprice 3D printer’s power supply. You can see it above, printed in PLA by the Monoprice mini 3D Printer. I love that this tiny printer just bangs out prints without fail time and time again.

You can download the STL file to print your own Power Supply Cooling Riser on Pinshape at this link: https://pinshape.com/items/33164-3d-printed-monoprice-mini-3d-printer-power-supply-cooling-riser

These risers are a fast and quick way to keep your powersupply cool. If you want you can use some glue or VHB and stick them to a flat surface. They fit snugly so you shouldn’t have issue with them falling off/over unless you move your printer around a lot. Check out my other upgrades for this great little printer on this blog. I have several more upgrades to share when I can find time to write/upload. If you print out one of these, I would love to see a picture of yours in action. Makes me super happy and keeps me motivated to make time to share things when I learn that someone finds some benefit of my projects.