I love working with wood and have been working with it since elementary school. I almost always have one or two woodworking projects going for those days when I want to sequester myself from life for a few hours in the shop. However, I can’t remember the last time I built a piece of furniture for myself. Usually I’m building something for a family member or friend, and occasionally a stranger who saw my wood craft or was referred from a past customer. This project is for myself and will see daily use.

The last time my brother in law visited I had him help me move a couch into my office. After putting the couch in place I was left with a very odd space that quickly accumulated clutter. I enjoy reading on the couch and use it when I video conference as well. A clutter spot was not acceptable. I took some measurements and quickly drew up a simple design for an end table to fill the space. I settled on a style that roughly falls between shaker and american country. Practical, simple and built Zac tough. Know yourself as they say, inevitably at some moment in the future this table will either end up as a bench or step stool. With this table’s mortise and tenon construction and thicker boards, it will be up to the task of supporting my large mass.

When designing the table, I originally included a shaker style drawer. When I started cutting the wood, I realized how small and useless the drawer would be in terms of storage. With small tables, the space needed for the drawer itself results in a loss of a large percentage of the available storage space. I decided I would go with a flip up top. However, with a lack of readily available hinges with the correct overlay, I changed to a lift off design. This way I maximized the storage space for my seldom used electronic wires and other small items.

I chose a simple Danish Oil Finish for this table. I like oil finishes. They are easy to apply and typically bring out the beauty of the wood grain. If you get a ding or scratch they are easy to repair by simply re-applying more of the oil. As this table will see tough daily use, in a few weeks when the oil has fully dried, I will take the top and put a few thin coats of a durable polyurethane to seal the top.

Not much to a small table like this, you can see the entire table stacked up on the saw prior to assembly in the above right photo.

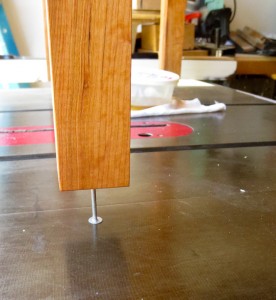

Some shots showing the details of the mortise and tenon work on the table.

Here’s a useful tip. When finishing table and chair legs. Drill a small shallow hole just undersize of a roofing nail. That way you can stand the project off with a roofing nail to allow prevent it from picking up any grit while the finish is drying. With oil finishes I also like to let the end grain soak up oil by resting it in a plastic tub full of the oil finish. End grain can soak up a lot of finish and this ensures it will be well sealed.

Cherry is a beautiful wood. Left au naturale cherry shows off a beautiful grain and color of the wood. Cherry darkens with time nicely but I enjoy the lighter feel of the natural wood when it is new. In a year this will be twice as dark. Part of the joy of Cherry is the gradual color change as the wood oxidizes. All to often people are quick to stain cherry dark.

In closing, I built this table almost entirely from wood I milled from a short cherry long my friends father had cut when we lived near each other as kids. He had this log in the garage for all these years. Late last summer he clearcut some trees and let me come snag a log to turn into lumber. In addition he gave me the cherry log he had kept in the garage. While the log was badly checked with cracks, I was able to get some usable wood and build this small project from it. Thanks Mr. Field for the log! This is what I did with the lumber I cut from it.