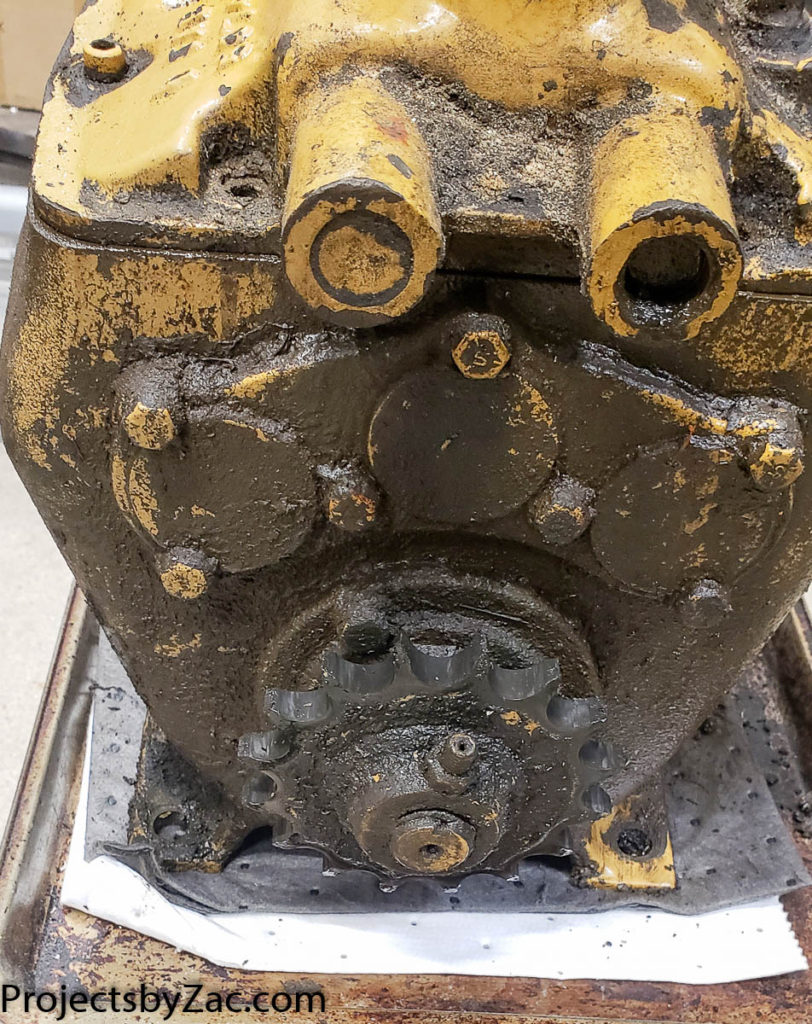

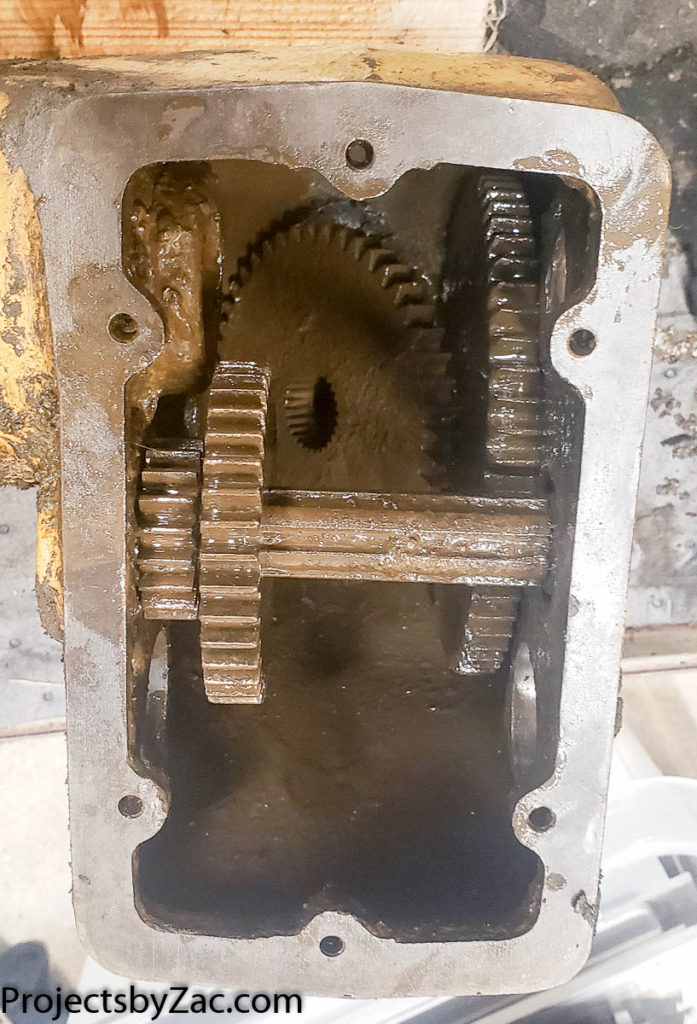

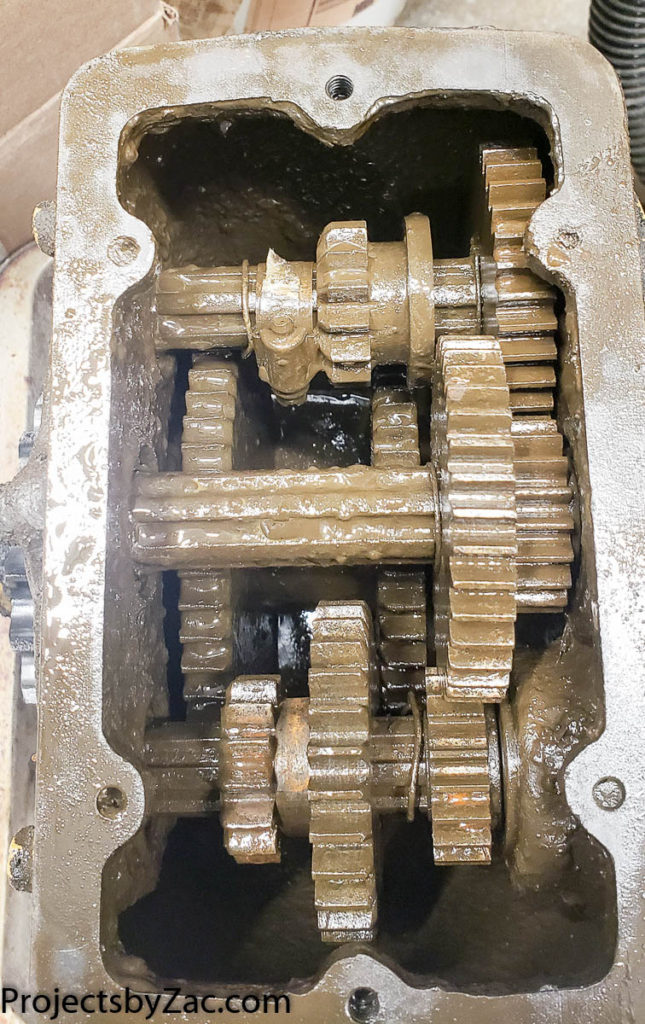

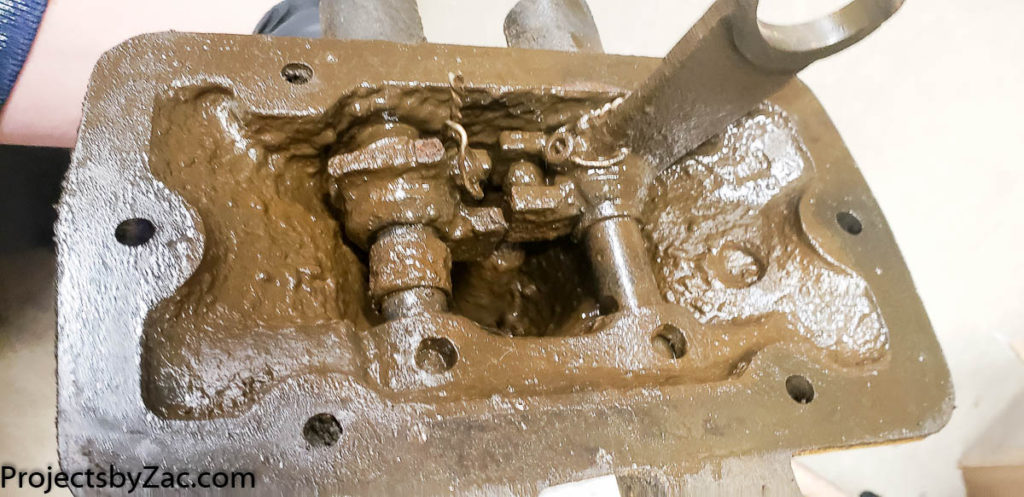

Take a good look at the photo below, Let it all soak in… Yes this is the state of the transmission when I took it apart. Makes you want to cry a wee little bit huh? But this worked, albiet loudly, it still ran even in this state.

Yes and that’s not the worst part of this whole dissassembly process. In the imortal words of the late great Billy Mays, “but wait there’s more!”

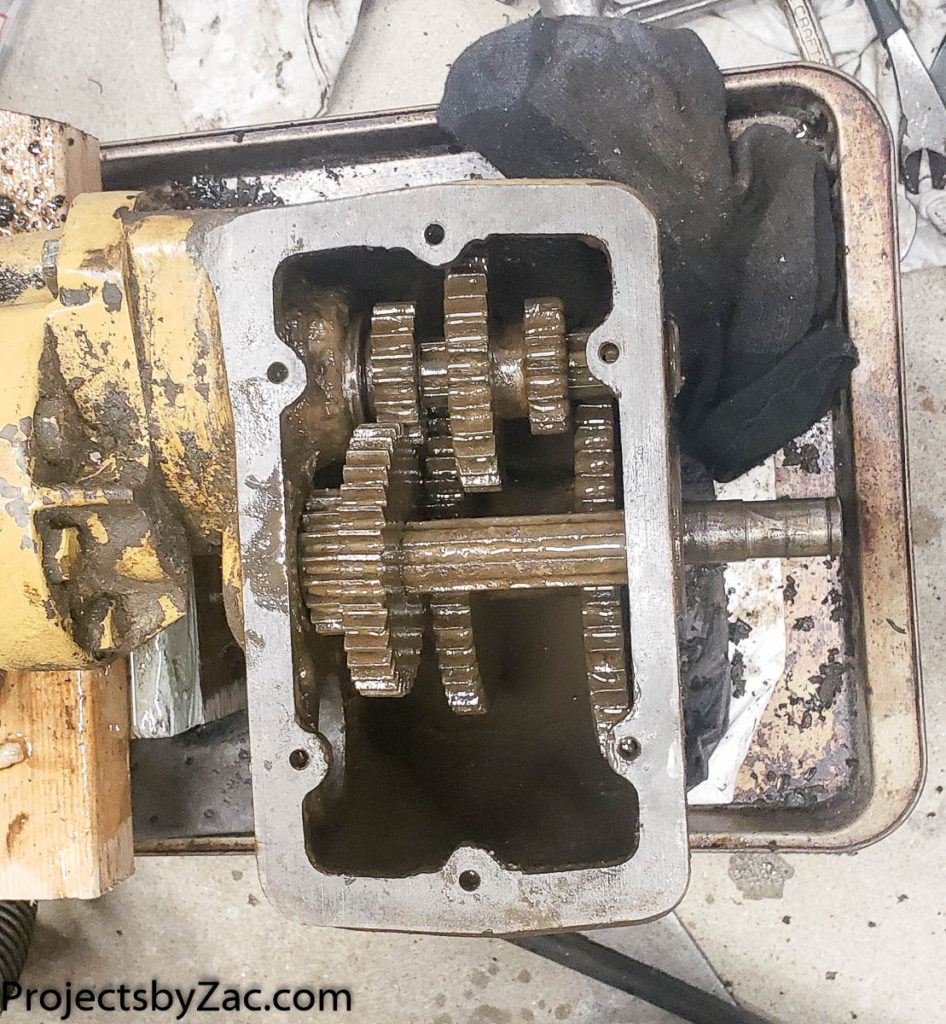

The only thing actually broken or wrong, outside of filthy, nasty yuck and a blown up bearing is that one of the shift forks is broken and gone. I’ll have to make a replacement. Thankfully the transmission is a symetrical design and I can use the existing one to aid in making the replacement. There are no parts for these lil dozers, so I’ll have to cast or machine my own new shift fork.

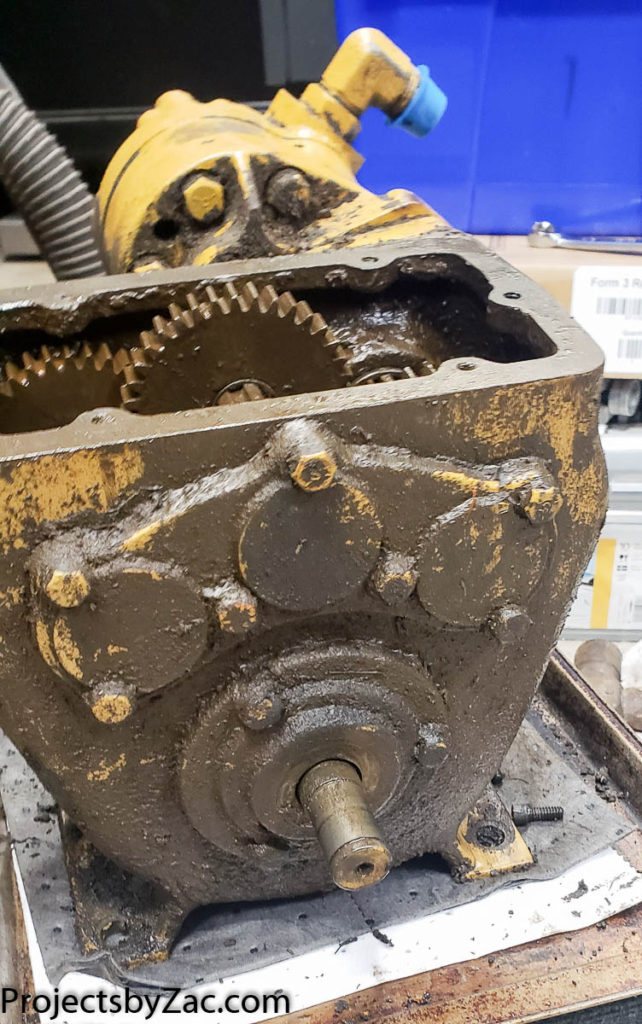

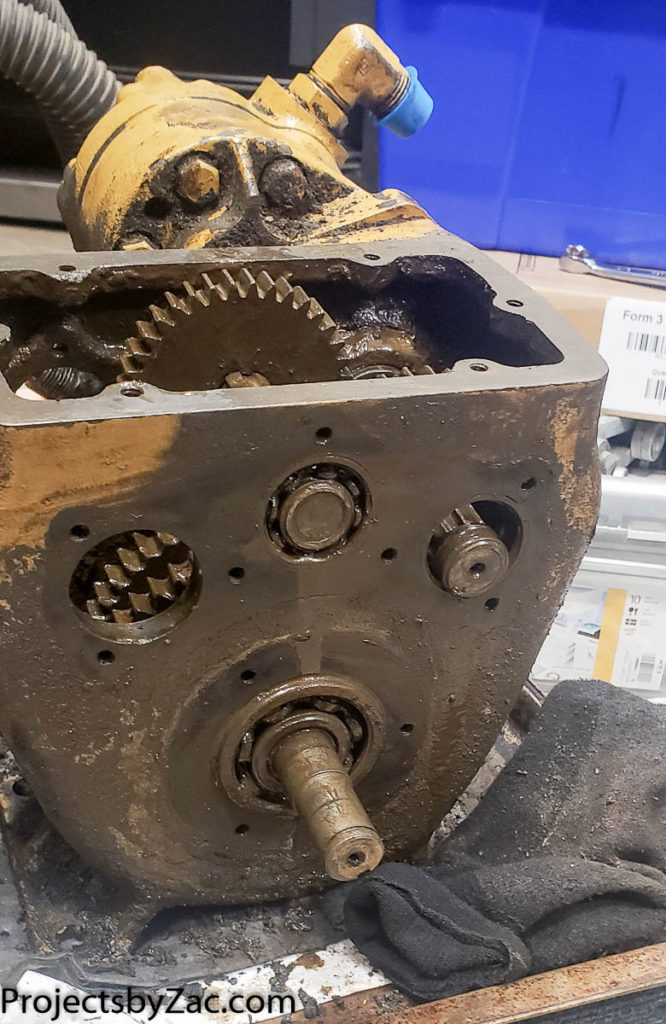

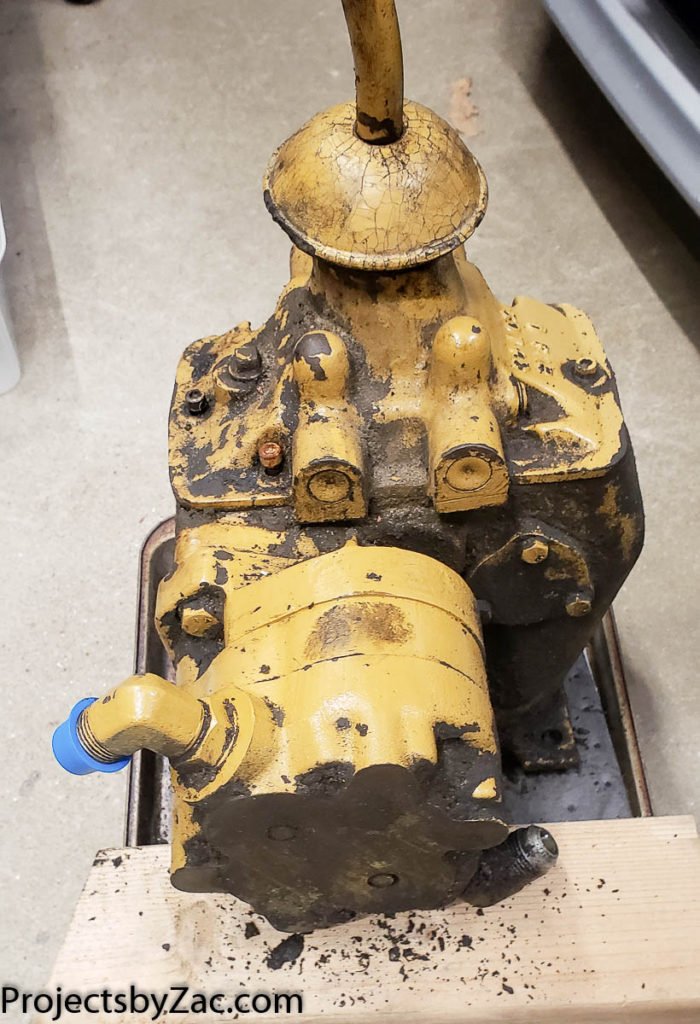

A bit about what I know about this transmission after taking it apart and studying it. The design is a three speed standard splined shaft transmission using sliding standard spur gears. A very simple and robust design, with nothing broken and no unbearable wear or damage despite it’s condition. Shafts, splines, sprockets, snap rings are all SAE. Only the bearings are metric. The three reductions of the tranmision are 1.5:1, 4.5:1, and 18.5:1. These are counted manually by turning the input shaft and counting after rebuild.

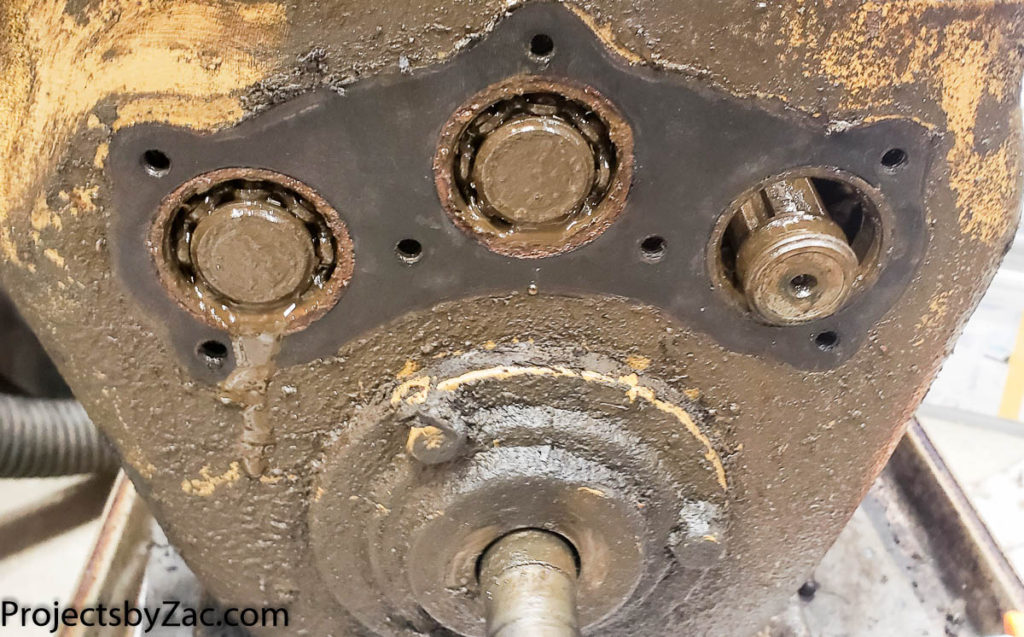

The main output shaft is 13/16″ for the sprocket. The bearing on the main shaft is a standard 6305 with bearing dimensions 25x62x17mm Deep Groove Ball Bearing. All of the other bearings are the same and are 6203 Bearings with dimensions 17x40x12mm. There is one oil seal on the output shaft it is an old out of production part Chicago Rawhide Oil Seal 8774, but a modern replacement exists if you can’t find the original. The modern replacement oil seal I found was a SKF 8796 LDS & Small Bore Seal, R Lip Code, CRW1 Style, Inch, 0.875″ Shaft Diameter, 1.624″ Bore Diameter, 0.25″ Width . I ordered this, and then found an original NOS part on Ebay and ordered that as well. they both have the same dimensions and basic design.

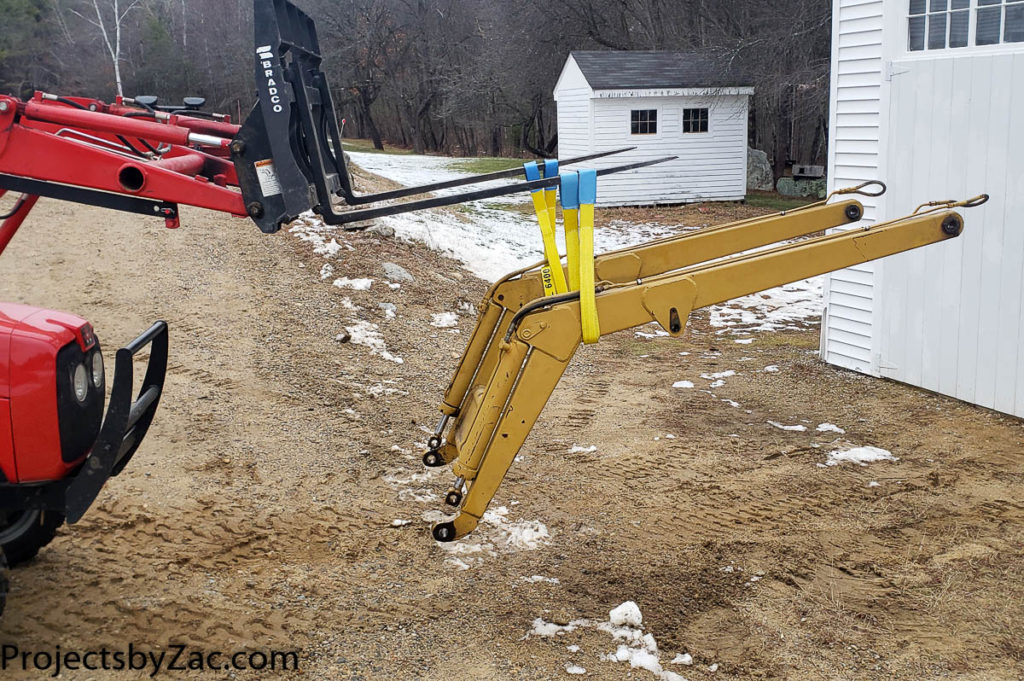

I’m going to just share the rest of the photos as a Gallery of the dissassembly of the 3 speed transmission in my Trackmaster dozer. Mine is a later model Trackmaster, with the hydraulic motor rather than a direct drive off of the motor. You are welcome to click through and look at them all. Dissassembly was relatively easy, with nothing being super siezed in place or broken other than the shift fork.

In the next post I’ll show some reassembly photos and talk a bit about the trick used to pull a blind bearing, cleaning advice for this kind of filth, and more.

If someone stumbles across this page with any information about these Dfab Engineering Trackmaster Dozers Crawlers, I’d love to know more. I’d be happy to host manuals and or parts catalogs here on my blog if you have them and are willing to share them with me. Please leave me a comment or email me at my website name on Gmail (no dot com there). I don’t check often, but I eventually will get back to you to host the information. Thanks!