This post is an early sneak peek at a project I have been working on in my spare time. I showed a friend who stopped by and he told someone else an I was pestered to share pics and a video. I have been experimenting with ducted fan thrust generation with a planned application. As for what that application is… Well it is not ready for the world yet and I will let you use your imagination.

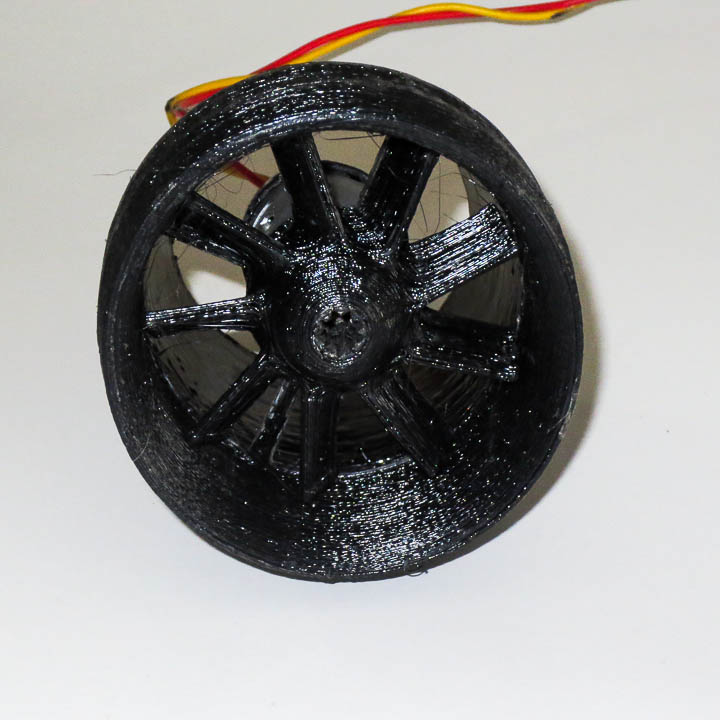

Mostly eye candy at this stage of the game, I have tested 3 different rotor designs without getting into complex blade geometries to date. I have primarily been focused on printing rotors that have little wall clearance and hand finishing them to minimize the gap between the duct and rotor blade. Research papers I have read shows that this area is critical to ducted fan efficiency and design.

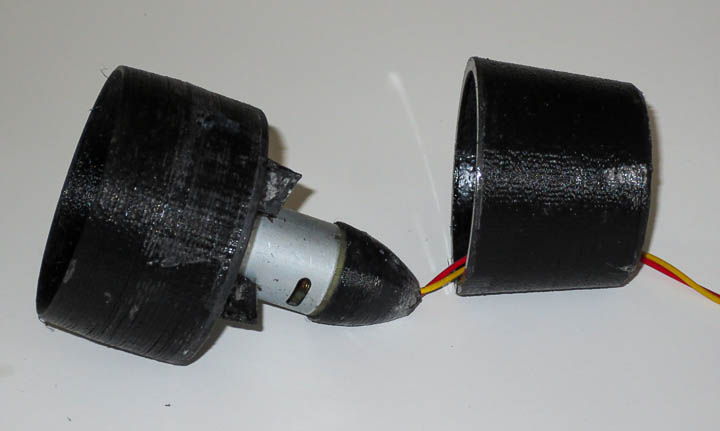

I am currently using a set up with a friction fit on a taper to lock the two halves together so I can get at the motor. This little bad boy screams when she spools up. In the shop it sounds like a mini jet engine starting up. I am working on test platform speed a controller for it using an Arduino nano and components..

You can see that this needs lots of cleaning and smoothing before final thrust measurements. I plan to put it through an acetone bath treatment and then do a bit of hand finishing to smooth out the inner walls to reduce any drag from the 3d printed irregularities. Eventually I’ll make a rotor balancing jig to fine tune the balance on the rotor. Future iterations will likely have continually reduced rotor mass to decrease inertia. I am testing behind a 1/4″ polycarbonate shield in case of catastrophic failure.

Here’s one with my hand to provide you with a sense of scale. I will try to get a video of it spinning at moderate speed. Without a speed controller I’m reluctant to limit test the high speed operation at this stage of development. I will put a video up here later this weekend if I can find time.

Here’s one with my hand to provide you with a sense of scale. I will try to get a video of it spinning at moderate speed. Without a speed controller I’m reluctant to limit test the high speed operation at this stage of development. I will put a video up here later this weekend if I can find time.