We all have them in our workshops, the cheap dual 48″ fluorescent tube shop lamps or “shop-lite”. The negatives of these low cost lamps being winter temperatures making them either not start, or flicker like crazy. I decided to try an upgrade using 12V DC LEDs using 3528/5050/5630 Flexible Light Strips. LED’s start instantly, don’t flicker even at very low temps, and my shop light conversion to LED’s decreases the energy consumed to about 20% that of the fluorescent tubes making it an environmentally beneficial green upgrade.

We all have them in our workshops, the cheap dual 48″ fluorescent tube shop lamps or “shop-lite”. The negatives of these low cost lamps being winter temperatures making them either not start, or flicker like crazy. I decided to try an upgrade using 12V DC LEDs using 3528/5050/5630 Flexible Light Strips. LED’s start instantly, don’t flicker even at very low temps, and my shop light conversion to LED’s decreases the energy consumed to about 20% that of the fluorescent tubes making it an environmentally beneficial green upgrade.

Originally inspired by the number of dead tubes and starting ballasts in many of my shop lights I went to my local Home Depot and Lowes to look at replacing and repairing these lights. However the price of both the tubes and shop lights has increased greatly since I last purchased some. Additionally there’s a buck a tube fee to dispose of the tubes now. I decided I could do it cheaper and better with LED lighting, but once again the ones I could purchase were quite pricey at ~$40 a piece. I had used some of the 3528 led light strip (about $6 for 5 meters) inside my 3D printer enclosure in the past and it worked amazingly well. I also have a plethora of free 12V dc power supplies in my parts bins making a light conversion to LED cost me about $3. Seemed like a win win situation, I’d use up some parts on my shelves, save money, and make a lamp that was considerably greener then the fluorescentversion making me feel better about my lowered impact on the environment.

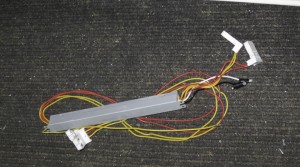

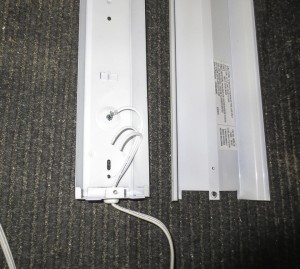

A pretty easy project, it starts with disassembling the old light and removing the internal electronics. Open up the light, pull out the parts, and remove them from the lamp. This is one of the better shop lites I have. It has an actual electronic ballast unit, and it still worked so I removed it carefully and am saving it for a future project or repair. Some of these lights have really bad, poorly made ballast set ups that are scary when you see how unsafe the design is inside.

We are just using the body or sheet metal “shell” for our light conversion. I like the shop light look, and the sheet metal has angles that will help spread out the LED lighting, which radiates out at a fixed angle from a point source rather then in a full 360 degrees like the tube. Make sure you clean the metal well. Even after using some Lysol scrubbing wipes to clean them, I found an alcohol wipe still removed some grease from the surfaces. We want the 3M adhesive to have an oil free clean surface with which to bond when we apply our light strips to the frame.

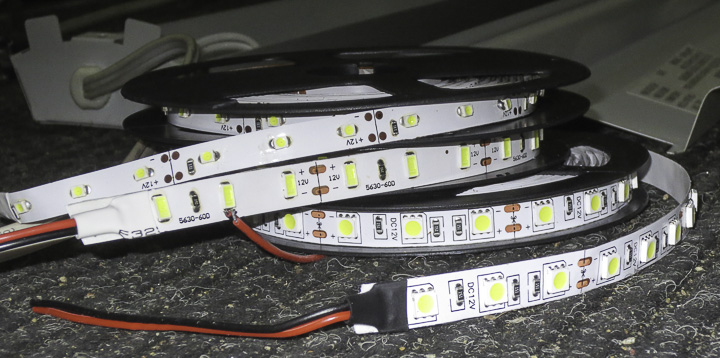

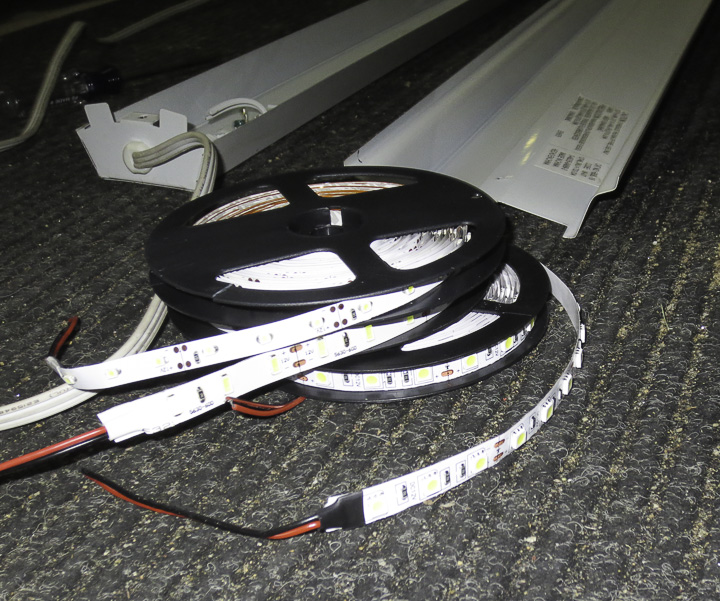

There are three common varieties of these LED light strips available at low cost on Ebay and other supply websites. They come in adhesive strip using 3528/5050/5630 LEDS. Additionally you can buy them in waterproof sealed strips for additional cost but I did not need them to be sealed. Above you see one 5 meter roll of each strip. They are very easy to work with. you cut them to length where you see the two copper tabs. Then you can easily solder strips together by connecting the end copper solder tabs. The different numbers refer to the actual dimensions of the LEDs. I’ll do a second post on what the differences are, as well as an evaluation of which one makes for the best shop light.

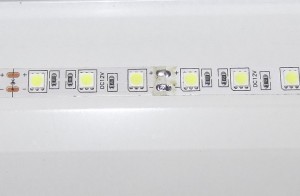

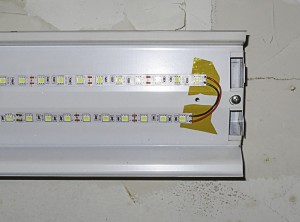

Application of the LED light strips to the shop lamp is very easy. Simply cut to length, being careful to cut in the middle of the small copper solder tab space. They have a cutting line for you to follow (you can see it on the left side of the right image below). Remove the adhesive backing strip and carefully place it onto your lamp. Be careful, the LED’s themselves are sharp, I use a bit of cloth folded up to apply pressure to the strip as I stick it down to save my fingers. Start on one end and kinda roll it down onto the metal of the shop light. Sometimes the copper tape gets kinked a bit from being on the roll. You want to maximize your adhesion by pulling and rolling out any bubbles or kinks as you work along the length sticking it down from one end to the other.

The strips are manufactured in shorter lengths and then soldered together connecting into long lengths. When I turned this particular section on, as you can see above, it did not light up all everywhere. The solder joint from manufacture had cracked and broken during the rolling or unrolling. If this happens, a quick touch up from a hot solder iron to the soldered tab (above right) will reflow the solder restoring a good electrical connection.

Connect up your 12V power supply. I’m using the 12V DC 2A kind that come with many electronics. I have a dozen or so in my parts bin. I pick these up for project use whenever I can. I did two different methods on my light conversion. One where I used the original shop light’s power cord. The other where I just directly soldered in the power supply cord to the light. Both are functionally identical. I can’t advise you as to which is better. For my purposes the decision was based on the shape/size of whichever power supply I was using. If it fit in the shop light body I kept the original cord. If not, I soldered the power supply wires directly to the strips.

When soldering the ends together, make sure you keep the + to the + and the negative to the negative. LED’s are diodes, and as such only flow current in one direction. If a whole strip isn’t working, likely you have the positive and negative backwards. I also put some Kapton (polyimide) tape underneath where the strips ended and I soldered. This was to ensure no electrical shorting to the light frame. You could just as easily use a piece of electrical tape but you want to make sure to add this safety feature to prevent any risk of electrical shock or shorting.

Testing the completed light is easy, plug it in. These lights are up in my shop now and working great. I’ll write a second post soon comparing the different LED’s ie 3528 vs 5050 vs 5630 in this application. I will share which one I feel is makes the best shop light, as there is a clear and away winner out of these three. Hope you enjoyed this quick post, learned something, and as always don’t follow online projects verbatim blindly, think, be safe, and be smart when working on your own projects.