Everyone has a bunch of items around the house that are in need of a new knob, button, clip, etc. Having a 3d Printer makes it easy to take care of these small repairs. One might argue that it’s not worth the cost, but is it really? Most parts needed for household repairs only use a few grams of ABS plastic when printed. Given the relatively low cost of the filament, there is no where you could buy replacement parts (even if you ignore gas or shipping costs) at even 2x the cost of making one yourself. I strongly suspect that in the future replacement parts will be printed on location rather then producing extras during a production run, cataloging, storing at a warehouse and then shipping them to a consumer with a broken item. It’s far easier and cheaper to email a part file then it is to deal with logistics of supplying replacement parts.

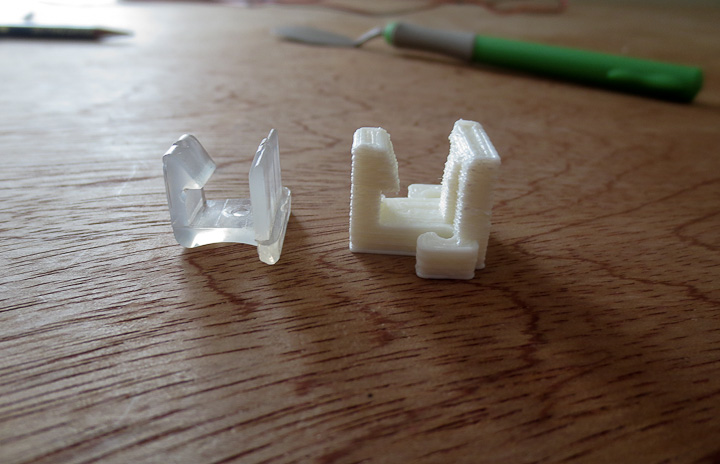

I have had the same fan since I was in college. It is made by Duracraft, and of the free standing, oscillating type. Over the years I’ve walked into it or knocked it over vacuuming a number of times. As a result, all of the small clips that hold the two halves of the wire fan guard had broken. This was the perfect time for a repair with a 3D printed replacement part. I took some measurements, quickly drew up the part in my favorite CAD software and printed one out. My first version was not quite right, so I made some slight modifications to make it perfect. In my design I included beefing up the strength of the clips by adding a little extra thickness to the part in critical locations based on where the originals had failed over the years. Printing out 5 of these small clips my fan is once again good as new and I am safely protected from the spinning blade once again.

My repair clips for the fan are better then the originals, cost about $0.90 each in terms of filament used, and now my fan has been saved from being prematurely thrown out while it still has many more years of life left in it.

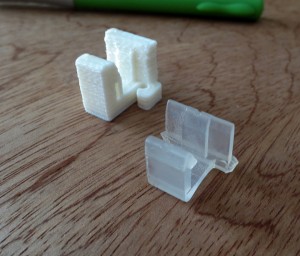

Similar to my Duracraft oscillating fan, I had broken the power button on my Rival High Performance Mixer years ago. I was still using it regularly but while making cupcakes one morning for a party, I realized I was sick of hurting my thumb every time I used my kitchen mixer. I sat down after the cupcakes went in the oven and by the time they were done baking I had designed and printed the white slide button you see in the above photos. It’s ergonomic, comfy and WAY better then the sharp bit of metal that was sticking up prior to my repair. I seem to recall the original was the same blue as the “power plus” buttons on the side but I can live with my white 3D printed replacement.

Once again, a useful household item was repaired at almost no cost for the repair part. I doubt there’s even $0.30 in the tiny button I designed and printed for my Rival High Performance Mixer. I expect to make lots of tasty things in the future with this great little hand mixer.

This last one will make all of my friends happy. My peanut car (aka a 2005 Ford Focus) has had a broken window crank for years. Originally broken on my side I swapped the broken one to the passenger side of the car. I never really had issue with the broken crank, but everyone who rides in my car complains (or at least comments on it). I did buy a replacement HELP! part at one point but it broke after only a short while. I decided it was high time I fixed this as I was in a repair things mood and I drew up a replacement knob for the window crank, printed it out, and installed it. It works better then the original part. It is likely stronger then it as well. ABS is a great material in terms of strength and impact toughness. The original had some flimsy polystyrene snap connector. I used an M4 bolt and washer to attache the knob in my design. Someday I may even paint it black to match the rest of the car.

In closing, 3D printing is not just for printing toys, or prototyping new designs. 3D printing can be used to cost effectively provide replacement parts for common household items. I read a paper recently that the Navy was retrofitting high end 3d Printers that can print in metal aboard all of the ships in the US Fleet. This makes a lot of sense logistically, as they no longer would have to stockpile critical spare parts. I can foresee that companies will someday offer replacement part .STL files directly to consumers to be 3d printed in the not to distant future. With 3D printers now available at Staples and soon to be in every home much like an inkjet printer I feel this day is assuredly not to far off.